Ramen

Ramen Machine and Production Solutions

Model no : SOL-RMN-0-1

Ramen is a type of noodle that is commonly used in many Japanese, Chinese, and Korean restaurants. Recently, the market demand for authentic Ramen noodles has increased in the North American and European regions. ANKO’s Commercial Noodle Machine can produce a wide variety of Noodles, such as Ramen noodles that remain firm when served in soups, robust Soba (buckwheat) noodles, traditional Japanese Udon noodles that are springy and chewy, as well as Korean Naengmyeon (cold noodles). ANKO’s NDL-100 Commercial Noodle Machine is highly recommended for professional Noodle manufacturers that need precision in their Noodle production process and are meticulous about their products’ presentation and textures. Please click on the link below to receive more information and a quotation for the machine.

Producing Authentic Ramen with an Automated Production Process

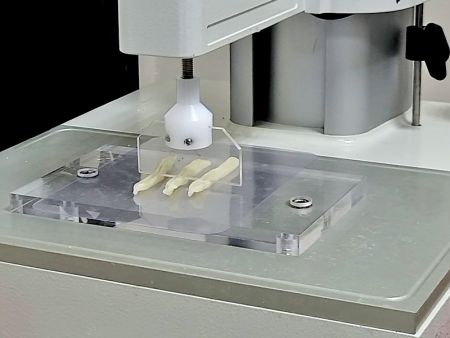

ANKO NDL-100 Commercial Noodle Machine has a unique extruding design; that can process a wide variety of doughs containing different ingredients and moisture content. Our machine can produce products in large quantities, such as thin Ramen Noodles (<2mm) that contain low moisture and have high sauce absorbability; or traditional Japanese Udon Noodles that are supple, as thick as 6mm in diameter and made with a high moisture dough. The machine can also produce delicate Soba (buckwheat) Noodles that have a low gluten-content.

The thickness/radius of the Noodles and the recipe can affect the texture, mouthfeel, and the ability of the Noodles to absorb sauces. ANKO’s Commercial Ramen Machine can produce Ramen with different thickness/radius, as well as making heart-shaped, fish-shaped, dumbbell-shaped, and triangular shaped noodles, at the capacity of 100kg per hour. The machine is compact in size (only 1.3 square meters), water resistant, easy to clean, and it takes less than 5 minutes to change the forming molds for producing different types of Noodles. The cold-water cooling system ensures that the quality and consistency of the Noodles are stable even at a high production rate. The machine has a user-friendly control panel and an ergo dynamic design which is suitable for different types of Ramen and Noodle manufacturing.

A great tasting bowl of Ramen relies greatly on the quality of the Noodles. ANKO’s Food Lab is well equipped to assist you with finetuning your recipes and developing the perfect Ramen Noodles. ANKO’s NDL-100 has the capacity to process various doughs made with a maximum of 35% non-wheat flour, and highly nutritious ingredients, such as fish pastes, whey protein, different flours milled from quinoa, buckwheat, chickpeas, and other grains. These Noodles are catering to consumers that are on a gluten-free, or high protein diet, as well as people who have special dietary restrictions or allergies.

NDL-100 is suitable for noodle manufacturers, central kitchens, chain restaurants, noodle shops, and food factories. ANKO’s professional team also offers production planning, equipment configuration, operational training, and recipe consultancy services to support and facilitate your Noodle productions business.

Food's Gallery

1

Filling / Forming

- Forming

Forming

When extruding Ramen Noodles with a 3mm diameter forming mold, the maximum capacity is 100kg per hour. By changing the forming mold, the ANKO NDL-100 can produce a wide variety of different Noodles. By adjusting the settings of the extruding speed, the length of Noodles, and the exact weight of each portion, the configuration of the noodles can be modified, and the product can be produced at a high efficiency rate.

Case Studies

Soup Dumping Production Line to Solve Insufficient Capacity

With business growth, a lack of supply and problems with staff management had come out. …

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

In Taiwan, most traditional noodle machines have good productivity but are limited in the types of noodles…

Xiao Long Bao Making Machine for Dutch Company

The client started his business by opening a restaurant in Netherlands, serving dim sum dishes.…

Soup Dumping Production Line to Solve Insufficient Capacity

With business growth, a lack of supply and problems with staff management had come out. …

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

In Taiwan, most traditional noodle machines have good productivity but are limited in the types of noodles…

Xiao Long Bao Making Machine for Dutch Company

The client started his business by opening a restaurant in Netherlands, serving dim sum dishes.…

Soup Dumping Production Line to Solve Insufficient Capacity

With business growth, a lack of supply and problems with staff management had come out. …

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

In Taiwan, most traditional noodle machines have good productivity but are limited in the types of noodles…

Xiao Long Bao Making Machine for Dutch Company

The client started his business by opening a restaurant in Netherlands, serving dim sum dishes.…

The Best Selection - Get Started with Us to Discuss Your Needs

Commercial Noodle Machine

ANKO’s Noodle Extruder machine is co-created with Taiwan’s Food Industry Research and Development Institute. This innovative commercial noodle machine can be used to produce large quantities of noodles with unique shapes, such as heart-shaped, fish-shaped and dumbbell-shaped, as well as triangle-shaped noodles that increase the surface area to help absorb sauces after cooking. This machine is only 1.3 square meters (14 square foot) making it suitable for specialty noodle producers, central kitchens, chain restaurants, and food factories of any size. The automated noodle production starts after the dough is loaded in the hopper and then the machine’s automatic portioning function does the rest. Productivity for 3mm diameter noodles can reach up to 100kg per hour. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More InfoSpecifications

Capacity: 100 kg/hr

Features

- Voltage can be designated.

- The length of ramen can be adjusted by parameter setting.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- DownloadsBest SellingRelated Food Solutions Type