Integrated Spring Roll Production Line

Model no : SOL-SPR-T-1

ANKO's "Integrated Spring Roll Production Line" is expandable, highly automated, and performs at great production efficiency. This unique design was developed and refined from our extensive experience with automated Spring Roll production lines. Each production process has been modularized and seamlessly connected to create ultra-high production efficiency with minimal labor requirements. The result is high product quality combined with ultimate production consistency. Based on each client's specific product requirements, we can customize production lines to meet diversified specifications.

To ensure production accuracy and consistency, ANKO modularized and automatically controls eight major components in the production line, including the filling conveying, Spring Roll forming, quick freezing, packaging, weighing, and the X-Ray inspection machines. Our machines are programmed to produce standardized 10cm Spring Rolls, and ANKO can also customize Mini Spring Rolls production solutions to meet specific product requirements. Click the button below to complete the form and provide us with your specific production requirements. Click the button below to complete the form to receive more information.

1

front-end

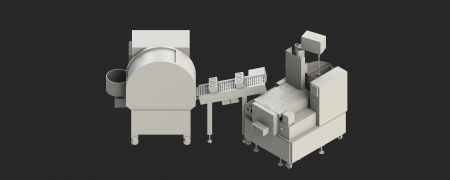

- ①Filling Feeding System

①Filling Feeding System

When low levels of filling in the hopper are detected, a warning mechanism will be automatically activated prompting employees to replenish the machine for uninterrupted production. The filling system has a maximum capacity of 100kg and may be adjusted to meet your production specifications.

- ②Batter Feeding System

2

mid-section

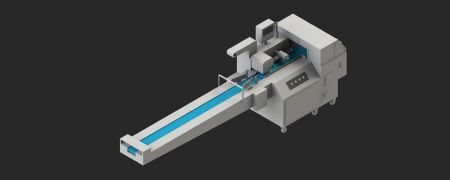

- ③Spring Roll Machine

3

back-end

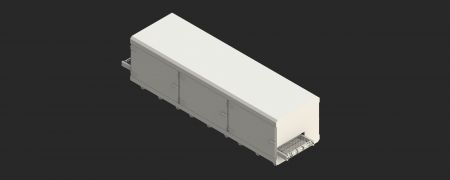

- ④Denesting System

- ⑤IQF / Freezer

- ⑥Packaging Device

4

quality control

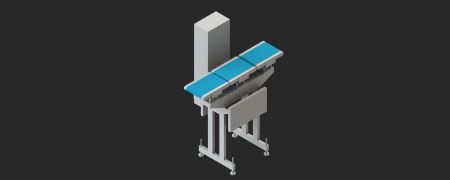

- ⑦Weight Inspection

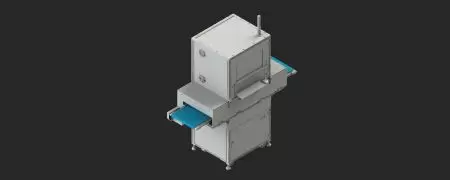

- ⑧X-Ray Inspection

- ⑨Environmental Monitoring

⑨Environmental Monitoring

Combining temperature and humidity monitoring with smart management, users can customize alert thresholds. When data exceeds the set range, instant mobile notifications are sent to reduce losses and enhance management efficiency. It also provides environmental data analysis and historical reporting features, enabling a high level of facility condition monitoring. ※Limited to regional sales

Features

-

Easy Assembling and Equipment IntegrationThe integrated spring roll production line has various components. Based on your existing equipment, we can assist with configuring compatible feeding systems, forming machines, automatic aligning, X-Ray inspection systems, and cooking equipment to optimize your production line.

-

Ultra-high Capacity Equipment ConfigurationANKO provides customized Integrated Spring Roll Production Lines, and we can also recommend preferred external equipment vendors.

-

Building Highly Automated Food FactoryProduction automation can significantly improve efficiency, shorten production cycles, and reduce required labor and costs, which can increase a food company’s market competitiveness.

-

Ensuring Food Quality and SafetyAutomated food production accurately controls each part of the process to ensure consistent product quality and meet required specifications. ANKO’s systems can also reduce artificial contamination, improve food hygiene and enhance overall food safety.

-

Gain Complete Control Over Environmental ChangesCombining intelligent temperature and humidity monitoring with efficient management, the professional team at Fox-Tech offers comprehensive solutions. For assistance, please contact: service@fox-tech.co or visit the Fox-Tech website.

- Best Selling