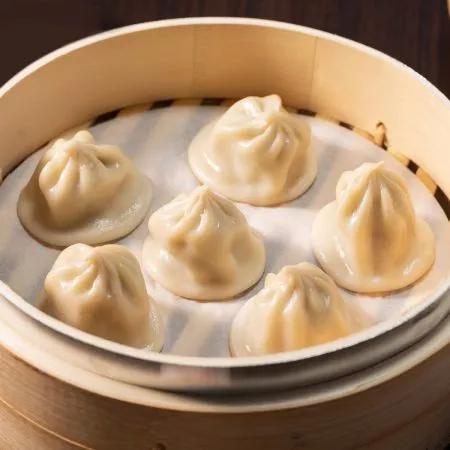

Xiao Long Bao Integrated Production Line

Model no : SOL-XLB-T-1

ANKO's "Xiao Long Bao Integrated Production Line" is highly automated and designed to produce "high quality" products with "great consistency." This integrated production line can be configured based on space availability to meet different specifications. We offer a selection of feeding equipment, forming machines, automatic aligning and rack loading machines, weighing scales, X-ray inspection equipment, gas steamers, and robotic arms. ANKO’s engineers will assist in ensuring the components are seamlessly connected and functioning correctly. We highly recommend this line for medium-sized and large food manufacturers and catering companies. Click the button below to complete the form to receive more information.

1

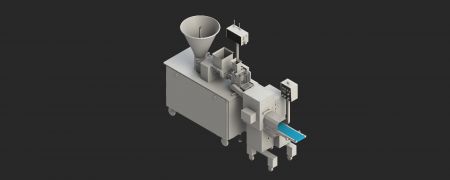

front-end

- ①Filling Feeding System ②Dough Feeding System

2

mid-section

- ③Xiao Long Bao Machine

③Xiao Long Bao Machine

The ANKO "HLT-700U Multipurpose Filling and Forming machine" and the "EA-100KA Forming Machine" are core to the Xiao Long Bao integrated production line, which has a capacity of 6,000 pieces per hour. Changing the forming molds allows you to make Xiao Long Bao with 9 or 12 pleats; and the dough and filling ratio can be adjusted to meet specific product requirements for customized Xiao Long Bao.

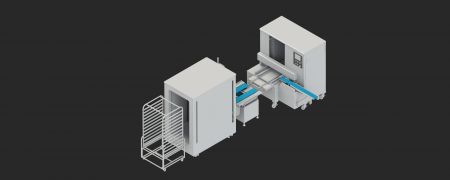

3

back-end

- ④Aligning Function ⑤Cooking Equipment / IQF / Freezer

4

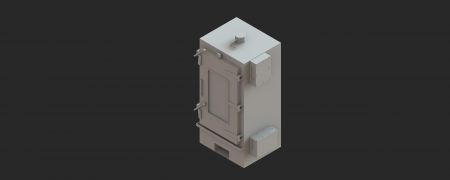

quality control

- ⑥Environmental Monitoring

⑥Environmental Monitoring

Combining temperature and humidity monitoring with smart management, users can customize alert thresholds. When data exceeds the set range, instant mobile notifications are sent to reduce losses and enhance management efficiency. It also provides environmental data analysis and historical reporting features, enabling a high level of facility condition monitoring. ※Limited to regional sales

Features

-

Ultra-high production capacity configurationANKO customizes the Xiao Long Bao integrated production line to meet your specific production capacity and product requirements.

-

Modularized Production ComponentsThe Xiao Long Bao integrated production line consists of various components. ANKO can integrate various options for feeding equipment, forming machines, automatic aligning devices, quality inspection machines, and cooking equipment into an existing production line configuration.

-

Construction of highly automated factoriesThe Xiao Long Bao integrated production line improves overall production efficiency, and significantly reduces labor requirements and cost. Giving you competitive advantages.

-

Ensure quality, health, and food safetyA fully automated production line with feeding equipment, conveyor belts, automatic aligning and rack loading machines, plays a crucial role in reducing human error. This, in turn, significantly reduces hazards caused by artificial contaminants ensuring high quality Xiao Long Bao production, and greater overall food safety.

-

Gain Complete Control Over Environmental ChangesCombining intelligent temperature and humidity monitoring with efficient management, the professional team at Fox-Tech offers comprehensive solutions. For assistance, please contact: service@fox-tech.co or visit the Fox-Tech website.

- Best Selling