Machine Trial

Have Inquiries about ANKO’s Equipment and Its Performances? We Welcome you to Schedule for a Machine Trial Testing with Us!

Before investing in any food machinery and equipment, you may question “Are ANKO’s machines suitable for our products? Will the recipes perform well under automation? Is the equipment hard to operate? Which other food factories or restaurants are using their machines? What other products can we produce with the same equipment? Or, will ANKO provide professional consultation and production planning advice?” Don’t worry, the answers will be included in the trial experience.

Our goal for Machine Trial Testing is to give “simulated production run”, “Troubleshooting”, build “Trust and Satisfaction”. Our team of consultants and engineers will support you to work toward a successful transition from manual to automated food production, as well as achieve the expected capacity, quality, safety, hygiene, and most important of all, the authentic flavors of the products. The trial is designed to be a one-stop-shop, which could test run recipes, verify problems and troubleshoot during the same visit. Moreover, there’s an in-house food lab built for various other food-related testing, such as boiling, steaming, cooking, or freezing, to increase the accuracy of the test results.

ANKO has over 47 years of industry advisory experience, and have developed more than 300 different types of products, the recipes include authentic Chinese, Indian, Latin American, Middle Eastern, Eastern European cuisines, etc., spanning across the global ethnic food market. Throughout the years, ANKO has had the opportunity to cooperate with business partners of various scales and from different sectors, allowing us to have access to an array of software, hardware and the ability to compare each machine’s uniqueness and advantages, which can enables us to work out more flexible procurement proposals that are also cost-effective.

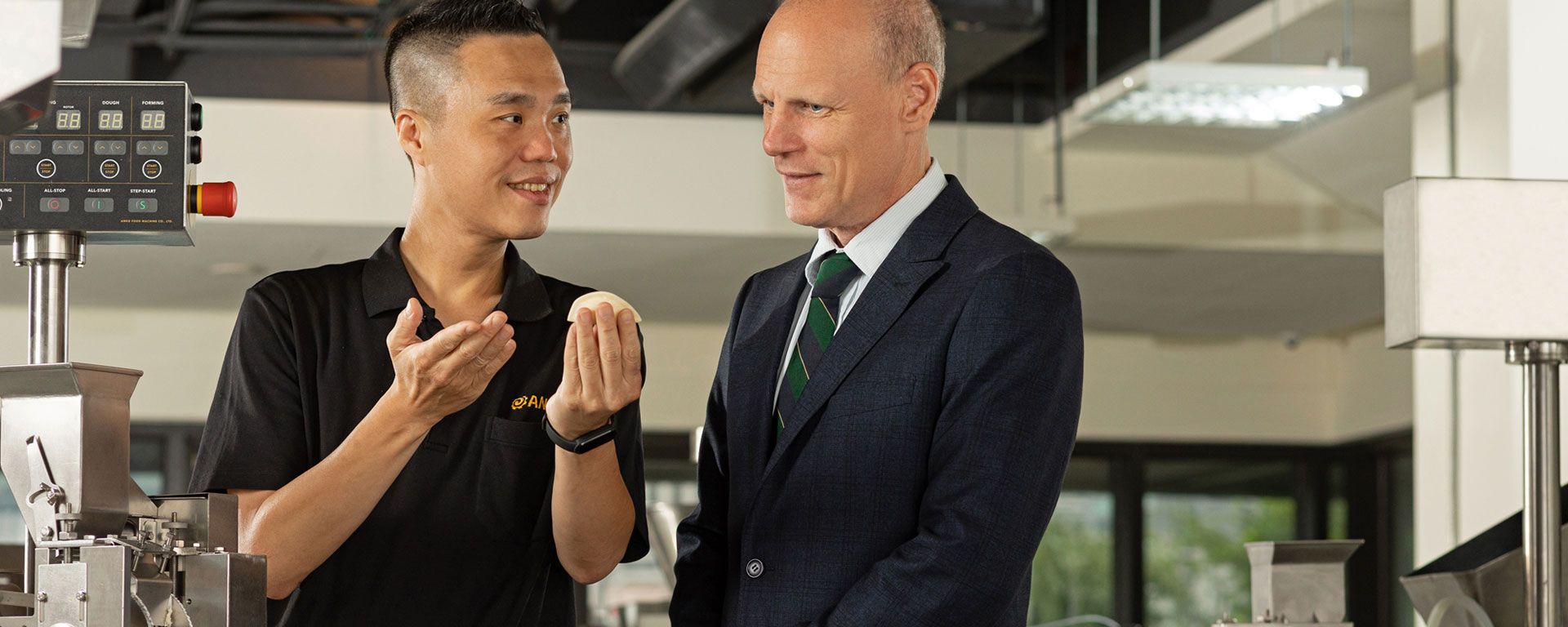

Simulating Actual Production Process, ANKO’s Team offers Full Service

Before scheduling for a trial testing, ANKO’s consultants will first have an in-depth understanding and evaluation of the current product production status, and your procurement requirements; then, according to the product specifications and expected capacity, we will arrange suitable machine models for the production trial testing.

- Machine Trial Testing Procedures: Schedule Appointment→ Ingredient Preparation → Production Trial Run → Final Product Testing → Evaluation and Fine-tuning

- Schedule Appointment – After the evaluation, the consultant will help set up an appointment with the specific machine model for the trial, as well as a set date and time.

- Ingredient Preparation – In order to achieve the best results, clients are welcome to send the main ingredients to our Taiwan headquarters in advance; or ANKO can help procure ingredients locally at your convenience. Our engineers will refer to the recipe provided and have the filling and dough prepared prior to your arrival.

- Production Trial Run – It’ll be a guided production test run with ANKO’s engineers. During the process, we will acquaint you with the specifications, productivity, functionalities, and other extensive use of the equipment. And our engineers are also open to any questions regarding the machines and production processes.

- Final Product Testing – Our factory comprises a fully-equipped “Food Lab”, supplied with kitchen gadgets, various raw materials, and ingredients to facilitate recipe fine-tuning and formula adjustments. We test the final products through steaming, cooking, frying, and/or freezing processes, in order to increase the accuracy of the tests more effectively.

- Evaluation and Fine-tuning – Products are evaluated and could be adjusted at different stages of the production. ANKO’s engineers can adjust the parameter and various parts according to the flow of operation. And our food researcher can assist with the ratio of pastry to filling, recipe modification, and food preservation approach, while other food product related problems could also be raised and solved as well.

Physical Location is Not a Problem! We offer Actual & Virtual Testing Services

ANKO offers both “Hands-On Onsite” and “real-time video” trials to help guide our clients with the machine test runs. Feel free to choose at your convenience without constraints.

1. Hands-On Onsite

Pay a visit to our headquarters in Taiwan, conduct the full experience at our factory starting from food prep, production to the final cooking process, and observe the operation procedures closely with details. And there’ll be “food researcher” to offer formula consultation to help improve the results.

2. Real-time Video

A video conference will be scheduled and ANKO’s team will provide real-time testing images, to help explain each step of the process in detail. The products will then be evaluated before and after it’s cooked. Any questions regarding the equipment and/or products could be raised, and ANKO’s team will provide guidance and supervision.

Need support?

Search for a topic or pick one below. We'll find you the best support options.