Crafting Perfect Vegetarian Spring Rolls with ANKO's Automated Food Machine

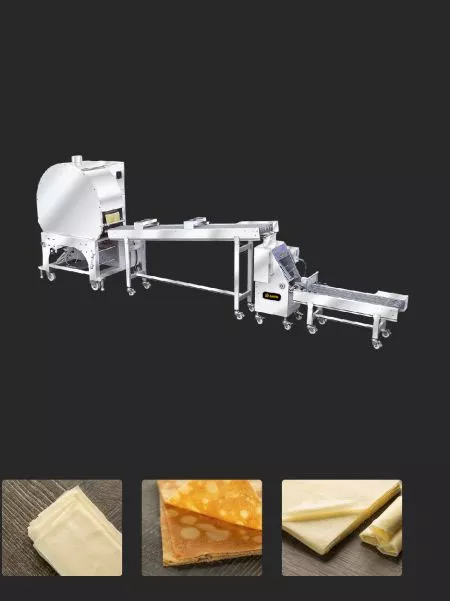

17 Jan, 2023ANKO Food Machine Company is a world-renowned automated food machinery manufacturer and a professional consulting company for automated ethnic food production. In 2023, ANKO will be proudly launching our brand new “SR-27 Automatic Spring Roll Production Line”. It is suitable for large food factories, central kitchens, and large-scale manufacturers to help resolve production issues related to the global labor shortage and rising wages. ANKO’s SR-27 has the capacity of producing 2,700 Spring Rolls per hour, and the unique filling system can process and extrude a wide range of ingredients. After loading the hoppers with raw materials, the automated production begins with a simple click. All the parts that have direct contact with food ingredients can be cleaned thoroughly and easily with water.

A Mechanical Design Leap! Handling Vegetable Fillings with Ease

Most Spring Roll Machines on the market have difficulties processing fibrous vegetable filling ingredients, and often require additional starch and cooking which affects the vegetables’ original crispness and crunchy texture. ANKO’s SR-27 Spring Roll Production Line is designed with a pressure-free filling hopper that simulates a hand proportioning mechanism, thus it can produce Spring Rolls with any mix of vegetable filling without any additives or pre-cooking the ingredients. This upgraded filling system does not over compress the food ingredients and they can retain their original textures. It can also process a wide range of filling ingredients, such as fibrous vegetables with low lubricity and cooked meats that have low viscosity.

ANKO’s SR-27 Spring Roll Production Line has a user-friendly touch screen control panel that is easy to use and has a built-in IoT system that enables remote production monitoring and supervision. The extra-large 50 Liter filling hopper drastically reduce the frequency for refilling. All machine parts that have direct contact with food ingredients can be washed with water directly and thoroughly, making the daily cleaning process fast and easy.

A Variety of Filling Ingredients, Perfectly Utilized with One Machine

The wrapping mechanism adopts handmade methods, and different parameter settings can be entered for processing fillings that consist of either all vegetables, cooked meat, or a mixture of vegetable and meat. Depending on the client’s product requirements, this Production Line can produce high quality Frozen Spring Rolls, Deep-fried Spring Rolls and Fresh Spring Rolls. ANKO understands how the slightest difference between brands of flours and filling ingredients can make a huge difference in an automated food production line. Hence, we have built the industry’s very first “Food Lab” that collects an extensive selection of food recipes from around the world, to assist you with customized Spring Roll product development to gain advantages in the marketplace.

Yahoo News Click here>

Worldbakers News Click here>

We would like to hear from you!Contact ANKO Now

Let us know your needs via "Inquiry Form" below. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.