Semi-Automatic Spring Roll and Samosa Production Line

Spring Roll And Samosa Maker

Model no : SRPF Series

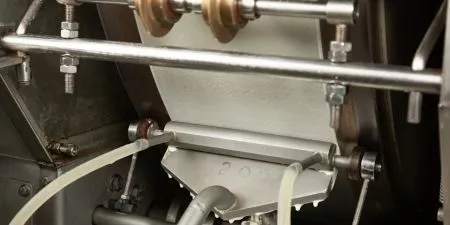

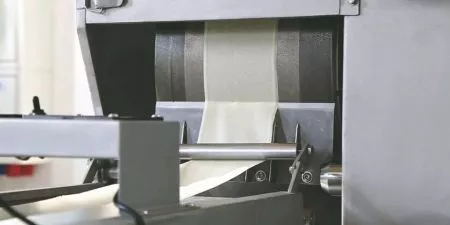

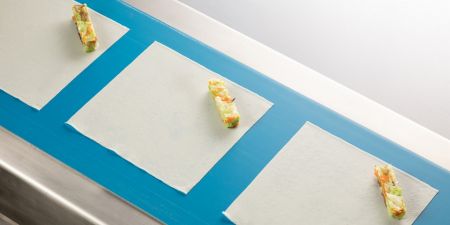

The Semi-Automatic Spring Roll and Samosa Production Line consists of a pastry making machine, a filling depositor, and a conveyor with working table for manual wrapping. The pastry making machine can produce spring roll pastry, samosa pastry, egg roll pastry, and even crepe, and the filling depositor can work well with a wide variety of filling. After pouring batter and filling in hoppers, the production line automatically bakes batter, cuts pastries, and deposits required amount of filling, and then workers can wrap spring rolls on the conveyor's working table. Moreover, the machine can connect with stacking machine to stack pastries alone for selling. Want to get a quick quote and consultant? Please click the button below and fill out the form.

How It Works

Specifications

- Dimension: 9,000 (L) x 1,300 (W) x 1,900 (H) mm

- Power: 45A (36 kW), 45B (39 kW)

- Capacity (pastry of 200 x 200 mm): 2,400 pcs/hr

- Thickness of pastry sheet: 0.4–0.8 mm

- Product weight: 30–80 g

- Filling weight: 20–50 g

- Including 1.3 m cooling conveyor and rotary cutter

- Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

-

Unique and Reliable DesignSimply feed the well-mixed batter and filling into hopper, machine will make pastry sheet, then cut and put the filling in, finally, manually roll up the products.

-

Process of ProductionMIXING -> FEEDING -> BAKING -> CUTTING -> FILLING -> GLUING -> WRAPPING & ROLLING BY HAND

- High capacity

Case Studies

Shrimp Spring Roll Pastry Machinery Design for an American Company

As for spring roll pastry import, high cost and quality degradation caused by rising temperature during shipping prompted the client to purchase a machine…

Automatic Samosa Pastry Sheet Machine - Machinery Design for Indian Company

In order to meet the demand of samosa, the supplier was looking for a food processing machine manufacturer providing high-quality…

Automatic Spring roll Production Line for Jordanian Company

How to determine the stickiness of stuffing which affect the depositor stability…

Machinery Design for a South African Company

The client's businesses, establishing in South Africa, extend from producing frozen food, baking products to central kitchen and catering service.…

Semi-Automatic Vegetarian Spring Roll Production Line – Machinery Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

ANKO Spring Roll Production Line – Machinery Design for a Jordanian Company

At the end of Ramadan, fasting was not required. Thus, the client received a large number of spring roll orders…

Automatic Samosa Pastry Sheet Machine– Machinery Design for Kuwait Company

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one…

Shrimp Spring Roll Pastry Machinery Design for an American Company

As for spring roll pastry import, high cost and quality degradation caused by rising temperature during shipping prompted the client to purchase a machine…

Automatic Samosa Pastry Sheet Machine - Machinery Design for Indian Company

In order to meet the demand of samosa, the supplier was looking for a food processing machine manufacturer providing high-quality…

Automatic Spring roll Production Line for Jordanian Company

How to determine the stickiness of stuffing which affect the depositor stability…

Machinery Design for a South African Company

The client's businesses, establishing in South Africa, extend from producing frozen food, baking products to central kitchen and catering service.…

Semi-Automatic Vegetarian Spring Roll Production Line – Machinery Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

ANKO Spring Roll Production Line – Machinery Design for a Jordanian Company

At the end of Ramadan, fasting was not required. Thus, the client received a large number of spring roll orders…

Automatic Samosa Pastry Sheet Machine– Machinery Design for Kuwait Company

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one…

Shrimp Spring Roll Pastry Machinery Design for an American Company

As for spring roll pastry import, high cost and quality degradation caused by rising temperature during shipping prompted the client to purchase a machine…

- DownloadsBest Selling