Egg Roll

Your Egg Roll Production Planning And Egg Roll Recipe Consultant.

Model no : SOL-EGR-S-1

The “egg roll production solution” provided by ANKO satisfies all your needs for the production of egg rolls, from the purchase of equipment, turnkey solution, to staff deployment. With years of experience in customer service and the food machine market, ANKO’s sales engineers not only help you select machines for your egg roll production line, from pastry making, forming, to packaging, but also provide comprehensive consulting services, such as production flow, factory layout, and recipe. In the solution below, the machines can be adjusted in model and quantity according to real production needs. Want to get a quick quote and consultant? Please click the button below and fill out the form.

About Egg-Roll Production Solution

The egg rolls made by ANKO Automatic Egg Roll Machine look and taste like handmade egg rolls. It is because that the folding and rolling device is designed based on the manual production process. Moreover, the machine is easy to operate. You just have to put prepared filling and dough belt in the machine. It can automatically cut dough belt into pastries, extrude filling, and roll up the pastries into consistent and high quality egg rolls. With the special filling device, the vegetable filling of egg rolls can be crunchy and crispy.

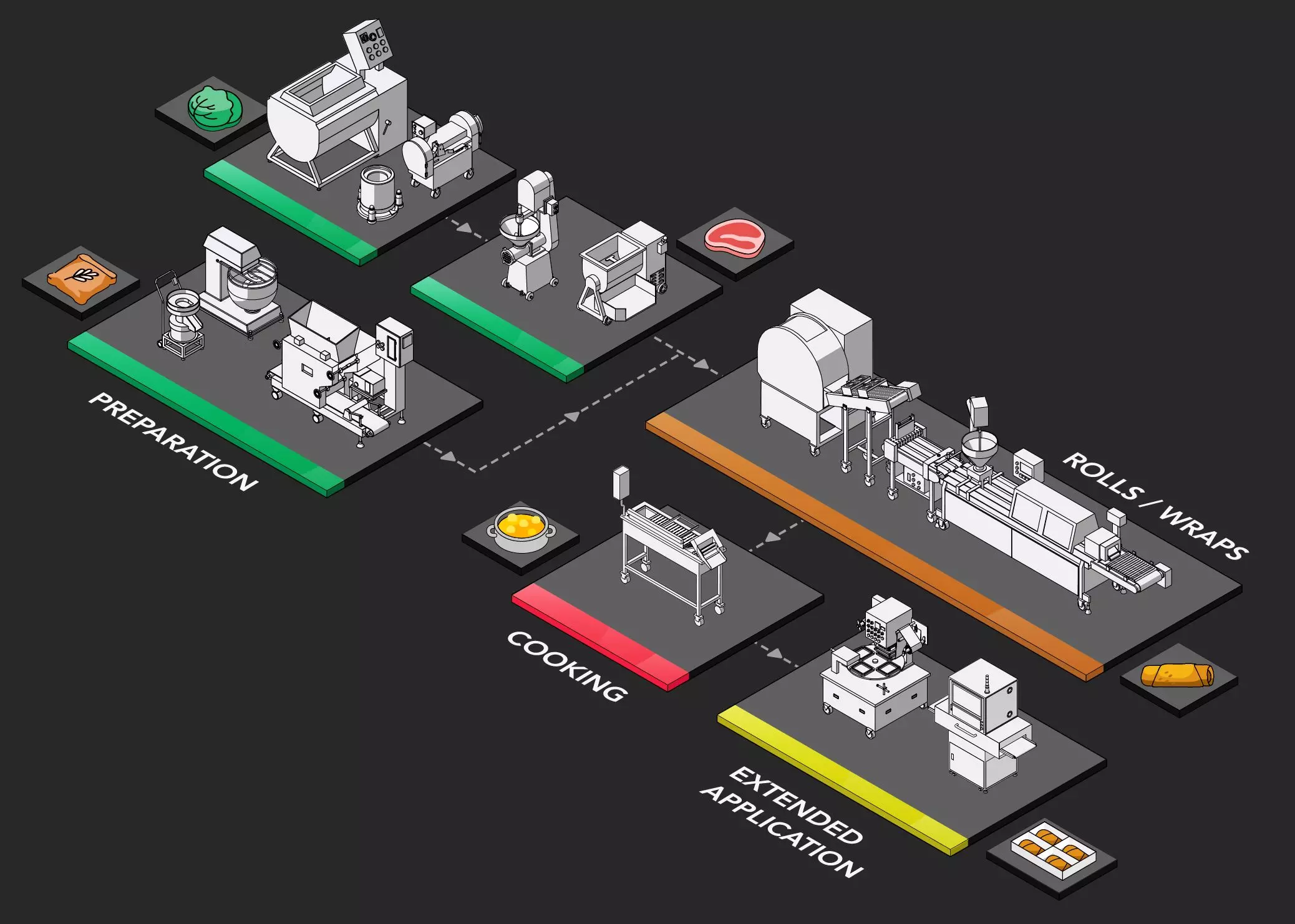

Turnkey and Production Planning

1

Preparation

- Sieving Mixing Vegetable Cleaning Vegetable Cutting Extracting Meat Mincing Seasoning Dough Sheeting

2

Rolls / Wraps

- Sheeting / Wrapping

3

Cooking

- Frying

Frying

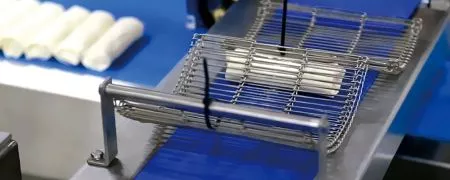

ANKO provides different types of deep-frying machines that you can choose from to suit your production needs. ANKO’s deep-frying machine is designed with a digital temperature controller to deep-fry every batch of egg rolls at the same temperature. The deep-fried egg rolls will be delivered by wire conveyor belt to facilitating collecting and packaging final products.

4

Extended Application

- Sealing Quality Control

Case Studies

ANKO Spring Roll Production Line – Machinery Design for a Jordanian Company

At the end of Ramadan, fasting was not required. Thus, the client received a large number of spring roll orders…

Cheese Spring Roll Automatic Equipment

Compare to Chinese spring roll, they are quite similar in the handmade production and crispy taste…

Spring roll Production Line for Jordanian Company

How to determine the stickiness of stuffing which affect the depositor stability…

Machinery Design for a South African Company

The client's businesses, establishing in South Africa, extend from producing frozen food, baking products to central kitchen and catering service.…

Spring Roll Production Line for a Canadian Company

The client runs chain restaurants and receives frozen food orders from supermarkets in Canada. Because of increasing demands…

Spring Roll Pastry Machinery Design For an Indian Company

The client is strict to control quality to ensure that consumers enjoy food with good quality and receive the best service. Due to business expansion…

Semi-Automatic Vegetarian Spring Roll Production Line – Machinery Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

ANKO Spring Roll Production Line – Machinery Design for a Jordanian Company

At the end of Ramadan, fasting was not required. Thus, the client received a large number of spring roll orders…

Cheese Spring Roll Automatic Equipment

Compare to Chinese spring roll, they are quite similar in the handmade production and crispy taste…

Spring roll Production Line for Jordanian Company

How to determine the stickiness of stuffing which affect the depositor stability…

Machinery Design for a South African Company

The client's businesses, establishing in South Africa, extend from producing frozen food, baking products to central kitchen and catering service.…

Spring Roll Production Line for a Canadian Company

The client runs chain restaurants and receives frozen food orders from supermarkets in Canada. Because of increasing demands…

Spring Roll Pastry Machinery Design For an Indian Company

The client is strict to control quality to ensure that consumers enjoy food with good quality and receive the best service. Due to business expansion…

Semi-Automatic Vegetarian Spring Roll Production Line – Machinery Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

ANKO Spring Roll Production Line – Machinery Design for a Jordanian Company

At the end of Ramadan, fasting was not required. Thus, the client received a large number of spring roll orders…

The Best Selection - Get Started with Us to Discuss Your Needs

Automatic Egg Roll Machine

The ER-24 can make various flavors of egg rolls with changeable filling depositors. After preparing a roll of dough belt, a maximum of 2,400 egg rolls can be made in one hour through automatic sheeting, cutting, turning, filling, folding, and rolling. The ER-24 is the ideal solution for making identical quality and tasty egg rolls that can compete with handmade ones. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More InfoSpecifications

Capacity:156 kg/hr or 2,400 pc/hr

*Based on 65-gram egg roll

Features

- Voltage can be designated.

- Vegetable cutter can julienne, slice, dice vegetables.

- Special filling device is suitable for large diced vegetables to get the texture you want.

- Special filling device is suitable for cooked ingredients, even loose cooked meat filling.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

What services and benefits are covered in the solution?

Custom-made egg roll production solution saves your time and makes you get all equipment from one single place

Different processing machines, from dough maker, forming machine, to packing and freezing machines, comprises a comprehensive automatic egg roll production line. ANKO provides solution service to save you searching and inquiring machines one by one. To ensure that the solution proposal is suitable for you, you could run your product through our machines in our well-equipped food lab. After your machines arrived, we can provide installation and training services. The costs from contacting each suppliers and other expenses will not bother you.

Egg roll equipment integration and effectiveness assessment are conducted by our professionals

With 45 years' experience in providing services for numerous food factories and central kitchens, ANKO is your professional turnkey project consultant in egg roll production. Based on your factory size and manpower, we can provide custom-made suggestions of egg roll equipment configuration and integration, wiring, production plan, and other details. In addition, ANKO assists you in thoroughly assessing the effectiveness of a solution and estimating manpower and time that could be reduced, which allows you to focus on operation and market development.

One specialist solving all your problems, making egg roll machine repair easy and painless

If your egg roll production line consists of machines from different suppliers, when they need to be repaired, it will be troublesome and time-consuming. In the long term, a burden of management will increase. ANKO supplies all kinds of egg roll production facilities and comprehensive after-sales services. Even though the facilities and services cover a wide range from ingredient preparing, food forming, frying, and packing machines as well as repair consultancy and service, all can be handled by one specialist to make machine repair and maintenance easy and painless.

"Taste of Tradition, Pioneer in Production", ANKO provides the most suitable suggestion on egg roll recipe

Every customer of ANKO is unique and important. From our 45 years of experience, we have enhanced our egg roll machines to make it better and collected more than 100 food recipes to offer you more comprehensive services. ANKO will always be with our customers to resolve difficulties, challenges, or questions about market experience, egg roll recipe adjustment, and production line planning to achieve greater success in preserving the taste of tradition.

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- Best SellingRelated Food Solutions Type