Pelmeni

Your Pelmeni Production Planning And Pelmeni Recipe Consultant.

Model no : SOL-PMN-S-1

With ANKO’s custom-made automatic pelmeni production line solution, you can have all manufacturing machines, plus a practical and comprehensive proposal taking into consideration the preparation of pelmeni filling, ingredient proportions of pelmeni wrappers, shape, cooking methods, package, and freezing. Whether you are new to automatic production or need to increase productivity, ANKO’s engineers can provide a professional and tailored solution. In the solution below, the machines can be adjusted in model and quantity according to real production needs. Want to get a quick quote and consultant? Please click the button below and fill out the form.

About Pelmeni Production Solution

ANKO's new automatic pelmeni machine - HLT-700U Multipurpose Filling & Forming Machine - is capable of mass-producing pelmenis with handmade pleats, full filling, and an attractive shape. In addition to the shaping mechanism, the filling extruding system of the pelmeni making machine is also upgraded to smoothly and stably extrude filling mixtures containing less oil, larger dices, high fiber, or loose cooked minced meat. Not only can the pelmenis be made plumper, but also a wider variety of filling is suitable for the machine, which make every pelmeni taste and look more like handmade.

HLT-700U has a built-in Internet of Things (IoT) system which is connected to the Big Data Analytics. It collects data from each production and be utilized with extended applications to manage production balances, warehousing and scheduling. This technology offers you full control over production by “monitoring the machine operational status, maintenance machine lifespan, and digital production management”. An alarm will inform you the exact part that needs inspection to reduce any possible risks.

Food's Gallery

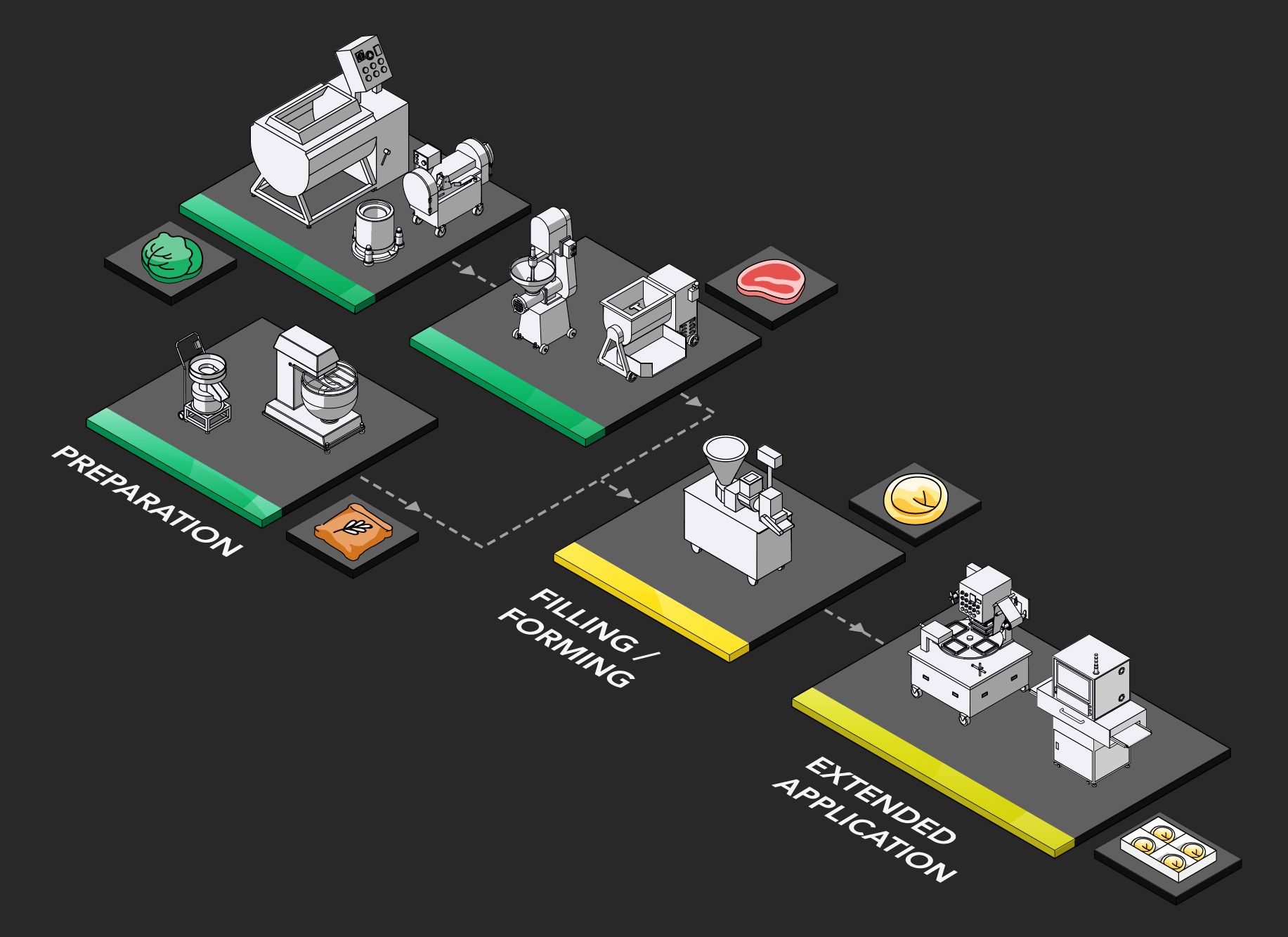

Turnkey and Production Planning

1

Preparation

- Sieving Mixing Vegetable Cleaning Vegetable Cutting Extracting Meat Mincing Seasoning

2

Filling / Forming

- Forming

3

Extended Application

- Sealing Quality Control

Sealing

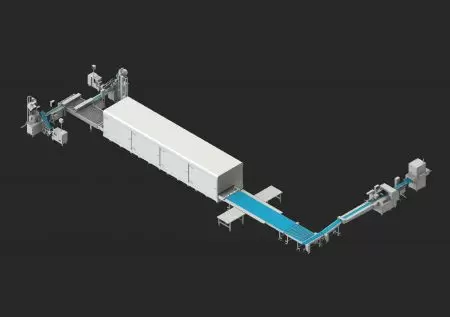

For packing needs, the packing machine is included in the pelmeni production line solution to pack pelmenis fast and smoothly and enable you to quickly deliver the products to every channel. If you need other machines, such as aligning machine, fryer, steamer, and freezer. ANKO's sales engineers can provide the most practical and affordable solution depending on your needs.

Case Studies

Spring Roll Production Line for a Canadian Company

The client runs chain restaurants and receives frozen food orders from supermarkets in Canada. Because of increasing demands…

Burrito Production Equipment Designed with Unique Folding Device

Compared to spring roll wrapper, tortilla is thicker and harder. Therefore, ANKO couldn't fold burrito with the folding device of…

Multipurpose Filling & Forming Machine - Machinery Design for a Tunisian Company

The client is an owner of a hotel chain in Tunisia. Speaking of cooking, their insistence on food has gained favor with visitors…

Shanghai Wonton Machine Design to Solve Labor Shortage

ANKO customized two rotary molds to help the client mass-produce shanghai wontons that were complicated to fold by hand…

Dumpling Machine Helps to Increase Capacity and Standardize Products

Consumers really liked the handmade dumplings, but "sold out" was the most important issue with which the company had to deal…

Dumpling Equipment Designed to Enhance a Food's Handmade Look

Sometimes machine-made dumplings cannot meet client's required shape. Thus, ANKO designed handmade pleats…

Semi-Automatic Blini Production Equipment Designed with Soft Pancake Stacker

Our agent gave a test run with ANKO's SRP for making blini, but failed to arrange them in a pile. Thus, ANKO's engineers developed…

Spring Roll Production Line for a Canadian Company

The client runs chain restaurants and receives frozen food orders from supermarkets in Canada. Because of increasing demands…

Burrito Production Equipment Designed with Unique Folding Device

Compared to spring roll wrapper, tortilla is thicker and harder. Therefore, ANKO couldn't fold burrito with the folding device of…

Multipurpose Filling & Forming Machine - Machinery Design for a Tunisian Company

The client is an owner of a hotel chain in Tunisia. Speaking of cooking, their insistence on food has gained favor with visitors…

Shanghai Wonton Machine Design to Solve Labor Shortage

ANKO customized two rotary molds to help the client mass-produce shanghai wontons that were complicated to fold by hand…

Dumpling Machine Helps to Increase Capacity and Standardize Products

Consumers really liked the handmade dumplings, but "sold out" was the most important issue with which the company had to deal…

Dumpling Equipment Designed to Enhance a Food's Handmade Look

Sometimes machine-made dumplings cannot meet client's required shape. Thus, ANKO designed handmade pleats…

Semi-Automatic Blini Production Equipment Designed with Soft Pancake Stacker

Our agent gave a test run with ANKO's SRP for making blini, but failed to arrange them in a pile. Thus, ANKO's engineers developed…

Spring Roll Production Line for a Canadian Company

The client runs chain restaurants and receives frozen food orders from supermarkets in Canada. Because of increasing demands…

The Best Selection - Get Started with Us to Discuss Your Needs

Multipurpose Filling and Forming Machine

ANKO’s most powerful Dumpling Machine, the “HLT-700U Multipurpose Filling and Forming Machine” is integrated with a new filling system! It can process large pieces of food ingredients, less oil, and high roughage fillings, as well as cooked meats that are less viscous. Not only it can handle a wide range of ingredients, but it can also produce dumplings that are plump and look handmade. This machine is compact in size (less than 1.5 square meters) and when forming dumplings at 25g per piece, it has the capacity of producing 12,000 pieces per hour. It is suitable for independently owned restaurants and large food factories. The IoT (Internet of Things) have been installed to ensure that the production can be overseen by managers in real time on a mobile device, and the data can be collected and processed through Big Data Analytics to support decision making. We have also installed a maintenance reminder program to ensure consistent productivity. Please click on the link below to fill out the form and our sales professionals will get back to you with customized solutions for your food production specifications.

More Info Compare searies machineCompare with Similar Models

| Model no | Multipurpose Filling and Forming Machine HLT-700U | Multipurpose Filling and Forming Machine HLT-700XL | Double-Line Multipurpose Filling and Forming Machine HLT-700DL |

|---|---|---|---|

| Description | Tasty Appearance as handmade look | A wide range of standard rotary molds are available | Highest production capacity |

| Capacity | 2,000 - 12,000 pcs/hr | 2,000 - 10,000 pcs/hr | 4,000 - 20,000 pcs/hr |

| Weight | 13 - 100 g/pc | 13 - 100 g/pc | 13 - 100 g/pc |

| More Info | More Info | More Info |

Specifications

Capacity:200 kg/hr or 8,000 pc/hr

*Based on 25-gram pelmeni

Features

- The built-in IoT function integrates the automated production line, and you can access this through remote monitoring via ANKO’s IoT dashboard.

- Voltage can be designated.

- Vegetable cutter can julienne, slice, dice vegetables.

- The thickness of pelmeni wrapper and the amount of filling can be adjusted by parameter setting.

- The shape of pelmeni can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

What services and benefits are covered in the solution?

One-stop pelmeni production solution allowing you to get all services from purchase to installation from one single place

In order to automatically make pelmenis, you have to buy a series of machines for washing, cutting, mincing, forming, cooking, and packing. Do you feel that you spend a lot of time and effort contacting different suppliers? ANKO provides pelmeni production solution to meet all your needs. Not only equipment, but also a professional food lab is available to help you ensure the machine and machine-made food satisfy your needs. Moreover, when your machine arrived, our installation and training services can help you save time and effort. All you need will be completed in one procurement.

ANKO provides industry-leading integrated services in pelmeni machines

ANKO's consulting team can help you compare different models to find the most appropriate pelmeni machine and install an affordable production line based on your needs and required production capacity. Also, we provide exclusive assessment and integration suggestions according to current conditions, workflow, factory layout, estimated time to put machine into operation, recipes, and other issues. The integrated and specialist service can greatly reduce the risk of purchase and, to meet your requirements, give you the best solution to keep smooth operation anytime.

One-stop pelmeni machine repair service offers you consistent service quality

Having different pelmeni making machines in your factory, you might need to contact different suppliers to get them repaired. ANKO assured you that all machines from ANKO would be handled properly. As long as the machine is bought from ANKO, no matter it is a vegetable cutter, mixer, pelmeni forming machine, or packing machine, you do not have to contact different people, all you need is to make a call to ANKO.

Food consultants with 45 years of experience help you with your pelmeni recipe

With 45 years of experience in the food machine industry, a wealth of market information, and detailed observation of the industry, ANKO can provide suggestions for equipment upgrades. Through direct interaction with our customers from 113 countries, we are well acquainted with the world's pelmenis and other related foods as well as consumer preferences. Whether it is about texture or taste, ANKO can offer advices on your recipes, even production and strategy in your target market with our general knowledge.

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

Would you like to find machines or integrated production line?

- Related Food Solutions Type