Empanada Making Machine

Empanada Making Machine

Model no : EMP-900

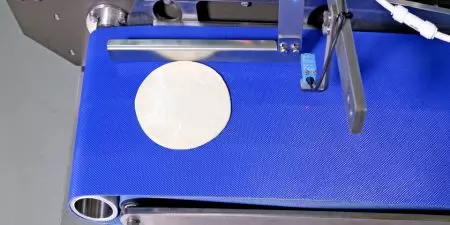

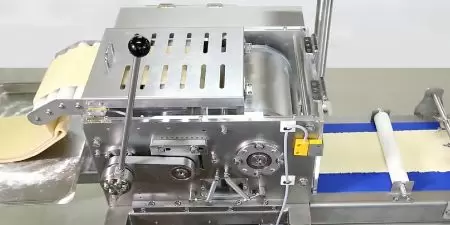

Explore the capabilities of ANKO's Commercial Empanada Making Machine! Paired with an Empanada Dough Press Machine, it requires only two simple steps to complete empanada dough pressing and forming, producing 3-6inch empanadas. We offer custom empanada pastry stamps to distinguish different flavors and for branding purposes. The production consistency and capacity ensure ideal quality products for food trucks, central kitchens, chain restaurants, and food factories.

We provide a comprehensive empanada production line that includes various food processing equipment, product-forming devices, deep fryers, and packaging machines. The layout and seamless integration of the production line can be customized to fit your factory space and floor plan perfectly. Click on the button below to complete the form and receive an initial quote. Our professional consultant will provide you with customized solution services.

How It Works

Food's Gallery

Optional Accessories

Pattern

| Flat Pattern | Traditional Pattern | Fork Pattern | Ladder Pattern with Double Sided |

|  |  |  |

In addition, we also provide Mold Customization, please click, click Learn More>

Specifications

- Dimensions: 2,740 (L) x 900 (W) x 2,140 (H) mm

- Power: 0.9 kW

- Capacity: 900 pcs/hr

- Product name: Empanada、Curry Puff、Calzone

- Product weight: 30–130 g/pc

- Suggested pastry thickness: 2–5 mm

- Filling hopper capacity: 45 L

- Air consumption: 400 L/min (@ 6 kg/cm^2)

- Weight (net): 415 kg

- Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

-

Extended Application - Dough Sheeting Cutter (DSC-220)DSC-220 is designed to divide premade dough sheets into individual pastry wrappers automatically. An additional Dough Recycling System reduces production wastage and costs.

-

Suitable for High Fat Content DoughsExamples are pie dough or puff pastry dough made with an oil water solution that contributes as much as 75% of the weight of the dry ingredients.

-

Improved Filling PerformancePrevents ingredients such as peas, corn kernels and other ingredients with a maximum radius of 10mm from being crushing during the filling process.

-

Special Filling DeviceCapable of processing raw or cooked ingredients with different consistencies and moisture contents.

-

Ejection Mold DeviceReplaces the manual demolding process and increases production efficiency.

-

Customized Product Forming MoldsHelps to increase product brand recognition, such as using company logos or using ANKO’s double sided print molds to create unique products.

-

Product Molds Can be Easily Assembled and DisassembledOnly two simple steps to switch from one production line to another.

-

Forming Molds are Made with Durable MaterialsThe “Clamping Mold Device” consists of one part made with Polyoxymethylene (POM) a food grade engineering thermoplastic material, and the other part is coated with Teflon to ensure food safety.

-

Automatic Dough Detecting DeviceInfrared sensor detects the radius of the dough wrapper and places the filling in the center, thus ensuring product consistency.

-

Water ResistanceThis machine can be easily cleaned and sanitized to ensure food safety.

Case Studies

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

Semi-Automatic Burrito Forming Machine Designed for the U.S. company

The client has run the company offering Mexican food for over 25 years. They not only have privately-held restaurant chains, but also…

Croquetas Automatic Production Line Design for an Indonesia Company

An ANKO client having had a successful food business in Colombia selling croquetas (croquette) to casinos and other retailers…

Kubba Automatic Production Equipment Resolved an Egyptian Client's Production Problem with Sticky Kubba Dough

The production demand has increased since the client sold products in multi-channel. Thus, he was looking for an expert of food machine…

EMP-900 Machine – Designed for producing Empanadas made with high fat content dough

ANKO has been approached by many companies and clients seeking a machine that can process high fat content dough…

Dumpling Machine Helps to Increase Capacity and Standardize Products

Consumers really liked the handmade dumplings, but "sold out" was the most important issue with which the company had to deal…

Calzone Automatic Production Machinery Design for a Tunisian Company

Due to the widespread reputation of their handmade calzone, they decided to buy a machine to meet the growing demand or the future…

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

Semi-Automatic Burrito Forming Machine Designed for the U.S. company

The client has run the company offering Mexican food for over 25 years. They not only have privately-held restaurant chains, but also…

Croquetas Automatic Production Line Design for an Indonesia Company

An ANKO client having had a successful food business in Colombia selling croquetas (croquette) to casinos and other retailers…

Kubba Automatic Production Equipment Resolved an Egyptian Client's Production Problem with Sticky Kubba Dough

The production demand has increased since the client sold products in multi-channel. Thus, he was looking for an expert of food machine…

EMP-900 Machine – Designed for producing Empanadas made with high fat content dough

ANKO has been approached by many companies and clients seeking a machine that can process high fat content dough…

Dumpling Machine Helps to Increase Capacity and Standardize Products

Consumers really liked the handmade dumplings, but "sold out" was the most important issue with which the company had to deal…

Calzone Automatic Production Machinery Design for a Tunisian Company

Due to the widespread reputation of their handmade calzone, they decided to buy a machine to meet the growing demand or the future…

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

- DownloadsBest Selling