Mochi

Your Mochi Production Planning And Mochi Recipe Consultant.

Model no : SOL-MCI-S-1

Since mochi is increasingly loved by consumers everywhere, the demand for mochi grows year by year. ANKO launches “mochi production solution”, providing comprehensive consultancy services to meet your needs for the automatic production of mochi, such as the purchase of equipment and factory layout planning. Machines, ranging from ingredient processing to mochi forming and packaging, can be found at ANKO. If you have questions about production flow, recipe, and staff deployment, one-on-one consultation with ANKO’s sales engineer is available to give you a tailored solution. In the solution below, the machines can be adjusted in model and quantity according to real production needs. Want to get a quick quote and consultant? Please click the button below and fill out the form.

About Mochi Production Solution

ANKO “SD-97W Automatic Encrusting and Forming Machine” can simplify the process of making mochi. Simply by putting steamed glutinous rice dough and filling into the hoppers, the machine can automatically and easily make chewy filled mochi. The machine-made mochi has high-quality, you can have mochi and flavorful filling in every bite. The encrusting and forming machine can work with different kinds of filling, such as peanut powder, sesame paste, bean paste, jam, and Mochi Ice Cream which thus can easily respond to the market demand.

SD-97W has a built-in Internet of Things (IoT) system which is connected to the Big Data Analytics. It collects data from each production and be utilized with extended applications to manage production balances, warehousing and scheduling. This technology offers you full control over production by “monitoring the machine operational status, maintenance machine lifespan, and digital production management”. An alarm will inform you the exact part that needs inspection to reduce any possible risks.

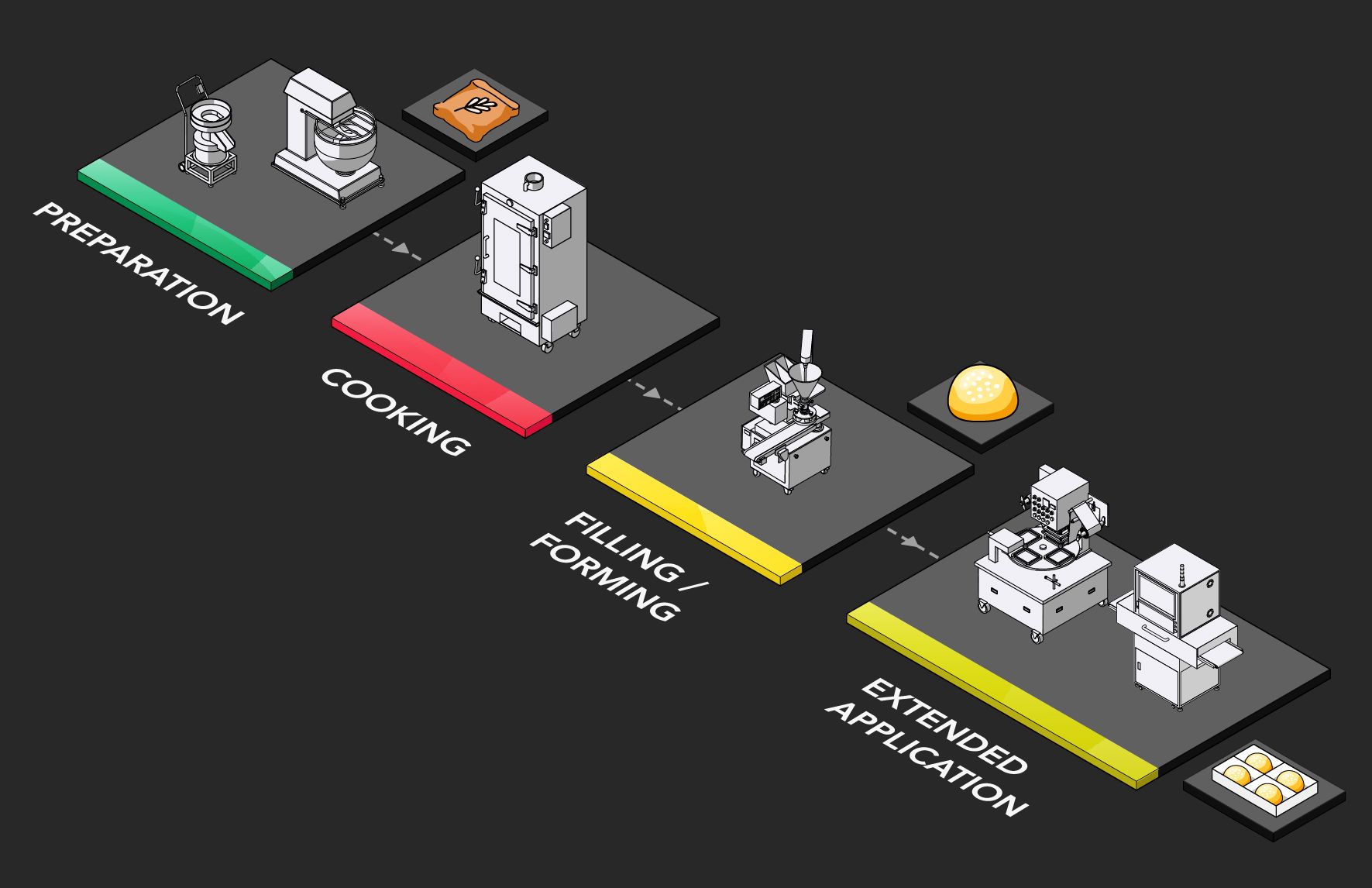

Turnkey and Production Planning

1

Preparation

- Sieving Mixing

2

Filling / Forming

- Forming

Forming

In this stage, the equipment is the key to producing quality mochi. The production process of filled and non-filled mochi: Non-filled mochi: Put steamed glutinous rice dough into the forming machine which then can automatically make mochi by dividing dough into small balls in required size and weight. Filled mochi: Put steamed glutinous rice dough and prepared filling into the forming machine. The thickness of mochi wrapper and the amount of filling can be adjusted according to your need. Then, the machine can automatically make consistent quality filled mochi.

3

Cooking

- Steaming

Steaming

The steamer combined in the production line is equipped with an auto water refilling device. Its high-efficiency heating system can heat up water to the boiling point within 15-20 minutes and generate a large amount of steam spreading evenly over the entire cabinet. A good choice to save energy.

4

Extended Application

- Sealing Quality Control

Sealing

For packaging mochi, ANKO provides professional packaging machine to increase efficiency, helping you to quickly deliver final products to every channel. Moreover, ANKO’s sales engineer can give you some advice on other machines such as vegetable cutting machine and seasoning mixer to suit your needs.

Case Studies

Table Type Automatic Encrusting And Filling Machine-Machinery Design for UK Company

In order to reduce labor cost, the client went to a machinery show and was impressed with ANKO's food machine…

Kibe Automatic Production Equipment Designed for a French Company

Kibe (Kibbeh) is one of the basic cuisines in the Middle East, so the high demand has made client's business booming. However, his employees couldn't meet…

Pineapple Cake Automatic Production Line Set up for New Product Launch

The client found that Taiwanese pineapple cake is very popular and delicious, so he decided to produce pineapple cakes and sell…

Croquetas (Croquette) Automatic Production Line Design for an Indonesia Company

An ANKO client having had a successful food business in Colombia selling croquetas (croquette) to casinos and other retailers…

Glutinous Rice Ball Machinery Designed to Solve Problem of Extruding Dry Filling

The client visited ANKO's booth at a Hong Kong exhibition for a solution to produce glutinous rice balls effectively…

Automatic Encrusting and Forming Machine - Machinery Design for Hong Kong Company

With current frozen equipment and packaging machinery, they would like to increase efficiency and develop other…

Kubba Automatic Production Equipment Designed to Solve the Forming Problem Caused by Sticky Crust

The production demand has increased since the client sold products in multi-channel. Thus, he was looking for an expert of food machine…

Table Type Automatic Encrusting And Filling Machine-Machinery Design for UK Company

In order to reduce labor cost, the client went to a machinery show and was impressed with ANKO's food machine…

Kibe Automatic Production Equipment Designed for a French Company

Kibe (Kibbeh) is one of the basic cuisines in the Middle East, so the high demand has made client's business booming. However, his employees couldn't meet…

Pineapple Cake Automatic Production Line Set up for New Product Launch

The client found that Taiwanese pineapple cake is very popular and delicious, so he decided to produce pineapple cakes and sell…

Croquetas (Croquette) Automatic Production Line Design for an Indonesia Company

An ANKO client having had a successful food business in Colombia selling croquetas (croquette) to casinos and other retailers…

Glutinous Rice Ball Machinery Designed to Solve Problem of Extruding Dry Filling

The client visited ANKO's booth at a Hong Kong exhibition for a solution to produce glutinous rice balls effectively…

Automatic Encrusting and Forming Machine - Machinery Design for Hong Kong Company

With current frozen equipment and packaging machinery, they would like to increase efficiency and develop other…

Kubba Automatic Production Equipment Designed to Solve the Forming Problem Caused by Sticky Crust

The production demand has increased since the client sold products in multi-channel. Thus, he was looking for an expert of food machine…

Table Type Automatic Encrusting And Filling Machine-Machinery Design for UK Company

In order to reduce labor cost, the client went to a machinery show and was impressed with ANKO's food machine…

The Best Selection - Get Started with Us to Discuss Your Needs

Automatic Encrusting and Forming Machine

Automatic Encrusting And Forming Machine can make either patterned or non-patterned products with a simple change of shutters; it can make either two colors or solid color with a simply change of dough hoppers. Not only the products with red bean paste, meat stuffing, or sesame paste but also plain products are producible. In conclusion, SD-97W can make dozens of ethnic foods such as meat bun, steamed bun, maamoul, meat pie, pan fried stuffed bun, mochi, crystal dumpling. Their look and taste are able to compare with handmade ones. The IoT (Internet of Things) have been installed to ensure that the production can be overseen by managers in real time on a mobile device, and the data can be collected and processed through Big Data Analytics to support decision making. We have also installed a maintenance reminder program to ensure consistent productivity. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More Info Compare searies machineCompare with Similar Models

| Model no | Automatic Encrusting and Forming Machine SD-97W | Automatic Encrusting and Forming Machine SD-97L | Automatic Table-Type Encrusting and Forming Machine SD-97SS |

|---|---|---|---|

| Description | Two color wrapper is available | Max. product weight up to 200 grams | Most compact machine |

| Capacity | 1,000 - 4,000 pcs/hr | 2,400 - 4,800 pcs/hr | 600 - 3,600 pcs/hr |

| Weight | 10 - 70 g/pc | 40 - 200 g/pc | 10 - 60 g/pc |

| More Info | More Info | More Info |

Specifications

Capacity:100 kg/hr or 2,000 pc/hr

*Based on 50-gram mochi

Features

- The built-in IoT function integrates the automated production line, and you can access this through remote monitoring via ANKO’s IoT dashboard.

- Voltage can be designated.

- The proportion of wrapper and filling is adjustable.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

What services and benefits are covered in the solution?

Want to expand mochi business? Let ANKO, a food machinery expert, do you a favor

Unfamiliar with mochi production line? No experience in production planning? Worried consulting mochi machine suppliers waste too much time or there is no training and reliable after-sales service? You can rest assured that ANKO, 45 years in the field, will handle your concerns. In order to resolve the difficulties that customers across the world have when purchasing, ANKO provides comprehensive "one-stop" service – front- and back-end equipment configuration, turnkey project planning, machine trial, and installation and training. ANKO's consultants have been praised by customers from 113 countries and are ready to assist you in improving performance and expanding unlimited business.

All your mochi production planning and questions will be handled by a professional

With 45 years' experience in manufacturing consulting service, we have the know-how to not only plan the most efficient production flow based on the layout of your factory, but also provide suggestions for machine installation, including electrical wiring and connection between machines according to your production of mochis. In addition, ANKO assists you in thoroughly assessing the effectiveness of a solution. For example, you could spend more time and money on business administration and development.

One specialist solving all your problems, making mochi machine repair easy and painless

If your mochi production line consists of machines from different suppliers, when they need to be repaired, it will be troublesome and time-consuming. In the long term, a burden of management will increase. ANKO supplies all kinds of mochi production facilities and comprehensive after-sales services. Even though the facilities and services cover a wide range from ingredient preparing, food forming, and packing machines as well as repair consultancy and service, all can be handled by one specialist to make machine repair and maintenance easy and painless.

Food consultants with 45 years of experience help you with your mochi recipe

With 45 years of experience in the food machine industry, a wealth of market information, and detailed observation of the industry, ANKO can provide suggestions for equipment upgrades. Through direct interaction with our customers from 113 countries, we are well acquainted with the world's mochis and other related foods as well as consumer preferences. Whether it is about texture or taste, ANKO can offer advices on your recipes, even production and strategy in your target market with our general knowledge.

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- Best SellingRelated Food Solutions Type