Kebab

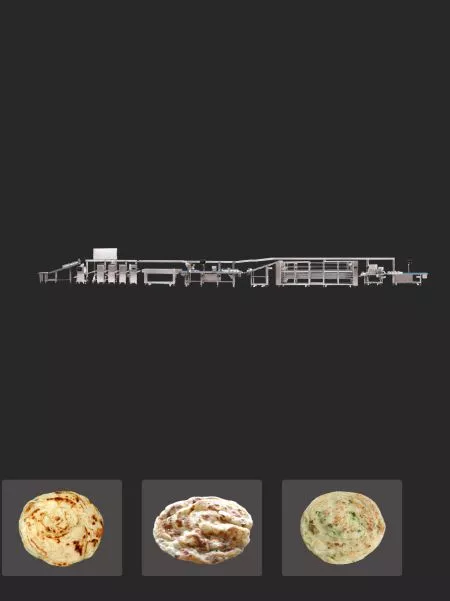

Professional Kebab Production Line

Model no : SOL-KBB-0-1

Doner Kebab, or simply “Kebab,” is a grilled meat dish that originated in the Middle East and was popularized in Turkey. Kebabs were introduced to different countries worldwide by Turkish immigrants, and they are now a trendy dish. Kebabs can be served by themselves or with dips, Pita, Naan, Arabic Bread, or other types of Flatbreads. ANKO’s SD-97 Series Automatic Encrusting and Forming machines can produce Kebab Meat strips and a variety of delicious Flatbreads. In the solution below, the machines can be adjusted in model and quantity according to real production needs. Want to get a quick quote and consultant? Please click the button below and fill out the form.

Customized Kebab Production Solution

Kebabs have become a ubiquitous dish worldwide. ANKO SD-97 Series machines can produce Kebabs with beef, lamb, chicken, and even “plant-based meat alternatives.” This ANKO machine can also make Kibbeh, Falafel, Maamoul, and many other authentic food products from the Middle East. ANKO also provides production solutions to help configure food processors, including commercial meat grinders, mixers, forming machines, and post-production packaging equipment to complete your Kebab production line.

SD-97M Automatic Encrusting and Forming Machine has a built-in Internet of Things (IoT) system which is connected to the Big Data Analytics. It collects data from each production and be utilized with extended applications to manage production balances, warehousing and scheduling. This technology offers you full control over production by “monitoring the machine operational status, maintenance machine lifespan, and digital production management”. An alarm will inform you the exact part that needs inspection to reduce any possible risks.

1

Filling / Forming

- Forming

Forming

ANKO’s SD-97 series machines can produce products ranging from 10 grams to 200 grams per piece. We can determine the most suitable model for you based on your production requirements and product specifications. Fully automated machines increase food productivity and quality while reducing production and labor costs.

Case Studies

Spring Roll Production Line to Expand Production for a Canadian Company

The client runs chain restaurants and receives frozen food orders from supermarkets in Canada. Because of increasing demands, they purchased machine from ANKO…

Kibbi Mosul Pastry Production Line Design for a Jordanian Company

Many Middle Eastern immigrants in western countries cannot forget the taste of hometown. Therefore, ANKO designed Kibbi Mosul Pastry Production Line…

Sambousek Automatic Production Equipment Designed with a Customized Half-moon Rotary Mold

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products…

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

Kubba Automatic Production Equipment Designed to Solve the Forming Problem Caused by Sticky Crust

The production demand has increased since the client sold products in multi-channel. Thus, he was looking for an expert of food machine…

Kibe Automatic Production Equipment Designed for a French Company

Kibe (Kibbeh) is one of the basic cuisines in the Middle East, so the high demand has made client's business booming. However, his employees couldn't meet…

Pineapple Cake Automatic Production Line Set up for New Product Launch

The client found that Taiwanese pineapple cake is very popular and delicious, so he decided to produce pineapple cakes and sell…

Spring Roll Production Line to Expand Production for a Canadian Company

The client runs chain restaurants and receives frozen food orders from supermarkets in Canada. Because of increasing demands, they purchased machine from ANKO…

Kibbi Mosul Pastry Production Line Design for a Jordanian Company

Many Middle Eastern immigrants in western countries cannot forget the taste of hometown. Therefore, ANKO designed Kibbi Mosul Pastry Production Line…

Sambousek Automatic Production Equipment Designed with a Customized Half-moon Rotary Mold

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products…

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

Kubba Automatic Production Equipment Designed to Solve the Forming Problem Caused by Sticky Crust

The production demand has increased since the client sold products in multi-channel. Thus, he was looking for an expert of food machine…

Kibe Automatic Production Equipment Designed for a French Company

Kibe (Kibbeh) is one of the basic cuisines in the Middle East, so the high demand has made client's business booming. However, his employees couldn't meet…

Pineapple Cake Automatic Production Line Set up for New Product Launch

The client found that Taiwanese pineapple cake is very popular and delicious, so he decided to produce pineapple cakes and sell…

Spring Roll Production Line to Expand Production for a Canadian Company

The client runs chain restaurants and receives frozen food orders from supermarkets in Canada. Because of increasing demands, they purchased machine from ANKO…

The Best Selection - Get Started with Us to Discuss Your Needs

Automatic Encrusting and Forming Machine

The Automatic Encrusting and Forming Machine can make a variety of food, ranging from Chinese bao, meat pie, sticky rice ball, sesame ball, Brazilian coxinha to Indian classic dessert rasgulla, and even the traditional Middle Eastern food - kibbeh, which is filled with loose meat and shaped like a rugby, can be formed and is comparable with handmade kibbeh. The machine can work with different dough and filling. Moreover, you can have food with different shapes and delicate pleats, simply by changing shutter unit, or install double dough hopper to make two-color food. All plastic parts in contact with food are safe and non-toxic, meeting food safety regulations. The IoT (Internet of Things) have been installed to ensure that the production can be overseen by managers in real time on a mobile device, and the data can be collected and processed through Big Data Analytics to support decision making. We have also installed a maintenance reminder program to ensure consistent productivity. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More Info Compare searies machineCompare with Similar Models

| Model no | Automatic Encrusting and Forming Machine SD-97M | Automatic Table-Type Encrusting and Forming Machine SD-97SS | Automatic Encrusting and Forming Machine SD-97L |

|---|---|---|---|

| Description | Making tasty appearance with shape of rugby | Most compact machine | Max. product weight up to 200 grams |

| Capacity | 1,000 - 4,000 pcs/hr | 600 - 3,600 pcs/hr | 2,400 - 4,800 pcs/hr |

| Weight | 10 - 70 g/pc | 10 - 60 g/pc | 40 - 200 g/pc |

| More Info | More Info | More Info |

Specifications

Capacity: 4,000 pcs/hr or 90 kg/hr

Features

- The built-in IoT function integrates the automated production line, and you can access this through remote monitoring via ANKO’s IoT dashboard.

- Voltage can be designated.

- The thickness of kebab and the amount of filling can be adjusted by parameter setting.

- The shape of kebab can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- DownloadsBest SellingRelated Food Solutions Type