Shumai

Your Shumai Production Planning And Shumai Recipe Consultant.

Model no : SOL-SHM-S-1

ANKO’s automatic shumai (siomai) production solutions enable increased production efficiency with professional equipment procurement recommendations and processing consultancy. The wrapper and filling ratio can be adjusted to produce high-quality shumai meeting your product requirements. Sizes can range from 14g to 80g per piece. ANKO has production solutions that can provide you with a professional automatic Shumai machine, as well as additional equipment such as a wrapper presser, Shumai forming/aligning machine, and the necessary packing equipment to complete your production line. ANKO also offers recipe recommendations to produce great tasting shumai. The solutions we provide below may vary depending on the actual production requirements. If you are interested in a quotation, please click on the link below and complete the form. ANKO’s professional consultants will get back to you with more complete information.

About Shumai Production Solution

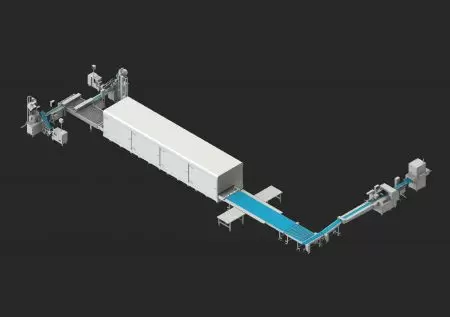

ANKO offers a “Double-Line” Shumai machine that has a maximum productivity of 6,000 pcs/hr., and a “Triple-Line” Shumai machine that has a high productivity of 9,000pc/hr. ANKO’s machines can start the production after loading the hoppers with pre-mixed dough and filling, then it can produce wrappers and form high quality shumai products. The amount of filling, and the relative height between wrapper and filling can be adjusted using the control panel to produce products that are uniformed in size and shape. The filling system presses the wrapper into the molds with filling, and forms shumai without breakage.

ANKO HSM-600 Automatic Shumai Machine can be combined with a garnishing device that can place green peas or diced carrots onto the products for a better appearance. This machine is designed with a unique filling system that can produce “extra large shumai”(dim sim) that are 80g per piece and can be filled with shrimp , and diced vegetables that all contribute to the texture of the product. The HSM-600 has a built-in Internet of Things (IoT) system which is connected to the Big Data Analytics. It collects data from each production and be utilized with extended applications to manage production balances, warehousing and scheduling. This technology offers you full control over production by “monitoring the machine operational status, maintenance machine lifespan, and digital production management”. An alarm will inform you the exact part that needs inspection to reduce any possible risks.

Food's Gallery

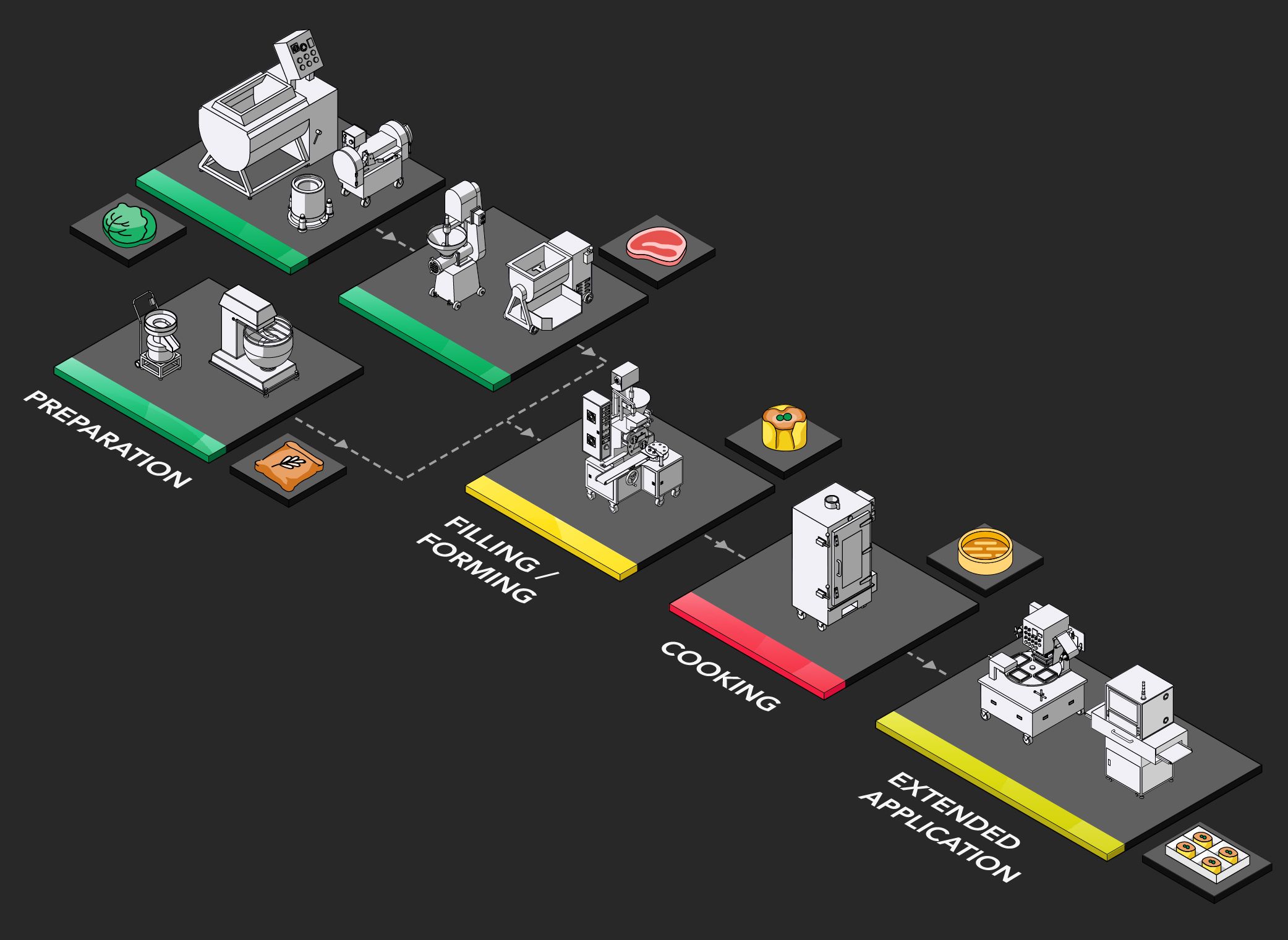

Turnkey and Production Planning

1

Preparation

- Sieving Mixing Vegetable Cleaning Vegetable Cutting Extracting Meat Mincing Seasoning

2

Filling / Forming

- Forming

Forming

ANKO develops the shumai forming machine to quickly and effectively mass-produce shumai. The shumai forming machine is capable of pressing dough into a thin dough belt and cutting it into square shumai wrappers. The filling system allows you to adjust the amount and height of filling as required. The garnish set and granule feeding set are optional for you to garnish your shumai with more colors, or put pea or carrot on the top.

3

Cooking

- Steaming

4

Extended Application

- Sealing Quality Control

Sealing

ANKO's shumai production line includes the packing machine, which enables you to quickly deliver the products to every channel. If you need other machines, such as aligning machine, fryer, and freezer. ANKO's sales engineers can provide the most practical and affordable solution depending on your needs.

Case Studies

Machinery Design for Mauritian Company

The client has a central kitchen to produce and sell shumai to retailers and takeaways...

Machinery Design for an Indonesian Company

The expansion and increase of business were followed by a problem that their original siomay...

Machinery Design for a Hong Kong Company

Only Anko provided reasonable price and excellent quality....

Automatic shumai machine designed to solve supply shortages of shumai

The client is a co-packer, who has been contracted by many food companies to produce Chinese food and dim sum. ...

Siomay Production Machine Designed to Solve Insufficient Production Capacity

Capacity In order to increase production capacity, the client switched from manual to automatic production and bought a semi-automatic siomay machine....

Machinery Design for Mauritian Company

The client has a central kitchen to produce and sell shumai to retailers and takeaways...

Machinery Design for an Indonesian Company

The expansion and increase of business were followed by a problem that their original siomay...

Machinery Design for a Hong Kong Company

Only Anko provided reasonable price and excellent quality....

Automatic shumai machine designed to solve supply shortages of shumai

The client is a co-packer, who has been contracted by many food companies to produce Chinese food and dim sum. ...

Siomay Production Machine Designed to Solve Insufficient Production Capacity

Capacity In order to increase production capacity, the client switched from manual to automatic production and bought a semi-automatic siomay machine....

Machinery Design for Mauritian Company

The client has a central kitchen to produce and sell shumai to retailers and takeaways...

The Best Selection - Get Started with Us to Discuss Your Needs

Automatic Shumai Machine

ANKO’s automatic triple-line shumai machine can make 9,000 shumai per hour, suitable for food factories, co-packers, and chain restaurants to boost production capacity of frozen shumai and ready-to-eat shumai. The production processes start from wrapper making, filling, forming, decorating, and arranging. Its flexibility enables you to make unique and delicious shumai by adjusting wrapper thickness, filling weight, appearance, decoration, and colors, or extend product line, such as shrimp shumai and fish shumai. In addition, the shumai machine is designed with an innovative arranging function, allowing you to adjust the distance between shumai in a row and between lines, which helps workers pack final products efficiently, or when automatically arranging shumai on trays with an aligning machine, you could minimize the distances and have the most shumai on a tray. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More Info Compare searies machineCompare with Similar Models

Specifications

Capacity: 9,000 pcs/hr or 225 kg/hr

*Based on 25-gram shumai

Features

- The built-in IoT function integrates the automated production line, and you can access this through remote monitoring via ANKO’s IoT dashboard.

- Voltage can be designated.

- Steamer is available with natural gas, bottled gas, or electricity.

- Vegetable cutter can julienne, slice, dice vegetables.

- The height of filling is adjustable.

- Can garnish your shumai with more colors or put topping.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain Businesses

Central kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & Investment

Machine distributor, Food Industry Investor

-

Food Service

Cloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

What services and benefits are covered in the solution?

Want to expand shumai business? Let ANKO, a food machinery expert, do you a favor

Unfamiliar with shumai production line? No experience in production planning? Worried consulting shumai machine suppliers waste too much time or there is no training and reliable after-sales service? You can rest assured that ANKO, 45 years in the field, will handle your concerns. In order to resolve the difficulties that customers across the world have when purchasing, ANKO provides comprehensive "one-stop" service – front- and back-end equipment configuration, turnkey project planning, machine trial, and installation and training. ANKO's consultants have been praised by customers from 113 countries and are ready to assist you in improving performance and expanding unlimited business.

ANKO provides industry-leading integrated services in shumai machines

ANKO's consulting team can help you compare different models to find the most appropriate shumai machine and install an affordable production line based on your needs and required production capacity. Also, we provide exclusive assessment and integration suggestions according to current conditions, workflow, factory layout, estimated time to put machine into operation, recipes, and other issues. The integrated and specialist service can greatly reduce the risk of purchase and, to meet your requirements, give you the best solution to keep smooth operation anytime.

Maintain shumai production efficiency, save time on primary decision

Many owners might have unpleasant experience of contacting customer service for shumai machine repair, especially when a problem is handled by different customer service specialists. The long process might affect shumai production capacity and lead to unexpected losses caused by shutdown and delivery delays. Hand over your concerns to ANKO! We provide a custom-made one-stop solution for you and assign a specific person to help all things from purchase to repair. Moreover, our comprehensive database records all your machine details to reduce the risks of loss someday.

"Taste of Tradition, Pioneer in Production", ANKO provides the most suitable suggestion on shumai recipe

Every customer of ANKO is unique and important. From our 45 years of experience, we have enhanced our shumai machines to make it better and collected more than 100 food recipes to offer you more comprehensive services. ANKO will always be with our customers to resolve difficulties, challenges, or questions about market experience, shumai recipe adjustment, and production line planning to achieve greater success in preserving the taste of tradition.

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

Would you like to find machines or integrated production line?

- Best SellingRelated Food Solutions Type