Maultaschen

Your Maultaschen Production Planning And Maultaschen Recipe Consultant.

Model no : SOL-MTC-0-1

ANKO's Maultaschen automation solution produces up to 12,000 pieces per hour, fully automating filling, forming, and precise weight control. This system streamlines complex manual work, effectively addressing labor shortages. With built-in IoT, you can remotely monitor production parameters in real time, ensuring an efficient manufacturing process. Ready to boost product quality and efficiency? Complete our inquiry form, and let us help you craft exceptional Maultaschen.

Customized Maultaschen Production Solutions

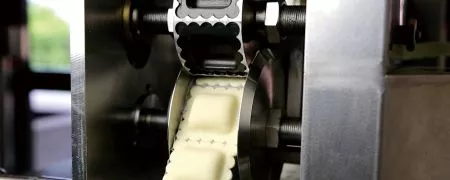

Maultaschen, a traditional German-style ravioli from southern Germany, features a thin wrapper filled with minced meat, spinach, onions, mushrooms, and cheese. Achieving a delicious Maultaschen requires a thin, elastic wrapper and a flavorful, balanced filling. ANKO's HLT-700U Multipurpose Filling and Forming Machine produces Maultaschen with a 1.1mm wrapper and fillings—beef, pork, or vegetarian—up to 10mm in size.

ANKO’s machine guarantees the ideal texture and appearance for your products, with over a hundred forming mold options and customizable designs to meet diverse market demands. The built-in IoT system offers three key advantages: real-time health monitoring, remote management, and digital production control, enabling you to manage your factory better.

We provide comprehensive Maultaschen production solutions, integrating commercial machines for food preparation, forming, cooking, freezing, packaging, and quality control. This automated line reduces labor needs and increases efficiency, addressing the global labor shortage. Whether you’re a small or mid-sized manufacturer or a large multinational, ANKO offers customized solutions tailored to your production needs.

1

Filling / Forming

- Forming

Case Studies

Fried Apple Pie Making Machine - Machinery Design for Panamanian Company

The client has run Korean restaurants in Panama, where are viewed by local people as a good place to satisfy your taste…

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

Semi-Automatic Burrito Forming Machine Designed for the U.S. company

The client has run the company offering Mexican food for over 25 years. They not only have privately-held restaurant chains, but also…

Automatic Wonton Production Line Design for a British Company

The client combined machine-made and hand-made processes, which turned the impression of uninteresting products made by machines…

Dumpling Machine Helps to Increase Capacity and Standardize Products

Consumers really liked the handmade dumplings, but "sold out" was the most important issue with which the company had to deal…

Calzone Automatic Production Machinery Design for a Tunisian Company

Due to the widespread reputation of their handmade calzone, they decided to buy a machine to meet the growing demand or the future…

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

The Noodle Extruder can be used to produce Spaghetti, Noodle and Noodles with Multi Structured, such as heart-shaped, fish-shaped, dumbbell-shaped, and…

Fried Apple Pie Making Machine - Machinery Design for Panamanian Company

The client has run Korean restaurants in Panama, where are viewed by local people as a good place to satisfy your taste…

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

Semi-Automatic Burrito Forming Machine Designed for the U.S. company

The client has run the company offering Mexican food for over 25 years. They not only have privately-held restaurant chains, but also…

Automatic Wonton Production Line Design for a British Company

The client combined machine-made and hand-made processes, which turned the impression of uninteresting products made by machines…

Dumpling Machine Helps to Increase Capacity and Standardize Products

Consumers really liked the handmade dumplings, but "sold out" was the most important issue with which the company had to deal…

Calzone Automatic Production Machinery Design for a Tunisian Company

Due to the widespread reputation of their handmade calzone, they decided to buy a machine to meet the growing demand or the future…

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

The Noodle Extruder can be used to produce Spaghetti, Noodle and Noodles with Multi Structured, such as heart-shaped, fish-shaped, dumbbell-shaped, and…

Fried Apple Pie Making Machine - Machinery Design for Panamanian Company

The client has run Korean restaurants in Panama, where are viewed by local people as a good place to satisfy your taste…

The Best Selection - Get Started with Us to Discuss Your Needs

Multipurpose Filling and Forming Machine

ANKO’s most powerful Dumpling Machine, the “HLT-700U Multipurpose Filling and Forming Machine” is integrated with a new filling system! It can process large pieces of food ingredients, less oil, and high roughage fillings, as well as cooked meats that are less viscous. Not only it can handle a wide range of ingredients, but it can also produce dumplings that are plump and look handmade. This machine is compact in size (less than 1.5 square meters) and when forming dumplings at 25g per piece, it has the capacity of producing 12,000 pieces per hour. It is suitable for independently owned restaurants and large food factories. The IoT (Internet of Things) have been installed to ensure that the production can be overseen by managers in real time on a mobile device, and the data can be collected and processed through Big Data Analytics to support decision making. We have also installed a maintenance reminder program to ensure consistent productivity. Please click on the link below to fill out the form and our sales professionals will get back to you with customized solutions for your food production specifications.

More Info Compare searies machineCompare with Similar Models

| Model no |

Multipurpose Filling and Forming Machine

HLT-700U

|

Multipurpose Filling and Forming Machine

HLT-700XL

|

Double-Line Multipurpose Filling and Forming Machine

HLT-700DL

|

|---|---|---|---|

| Description | Tasty Appearance as handmade look | A wide range of standard rotary molds are available | Highest production capacity |

| Capacity | 2,000 - 12,000 pcs/hr | 2,000 - 10,000 pcs/hr | 4,000 - 20,000 pcs/hr |

| Weight | 13 - 100 g/pc | 13 - 100 g/pc | 13 - 100 g/pc |

| More Info | More Info | More Info |

Specifications

Capacity: 12,000 pcs/hr

Features

- The built-in IoT function integrates the automated production line, and you can access this through remote monitoring via ANKO’s IoT dashboard.

- The thickness of maultaschen and the amount of filling can be adjusted by parameter setting.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain Businesses

Central kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & Investment

Machine distributor, Food Industry Investor

-

Food Service

Cloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- DownloadsBest SellingRelated Food Solutions Type