Vietnamese Rice Paper Spring Roll Machine

Rice Paper Spring Roll Maker

Model no : RPS Series

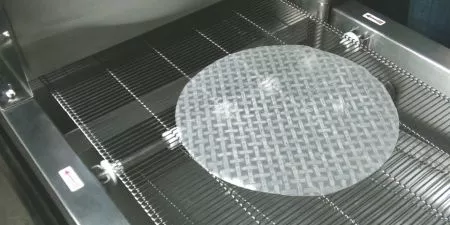

The RPS Series is designed with water spraying, steaming, softening, and filling devices, so workers only need to put rice papers on the conveyor and fold the spring rolls. You can also add a lifting device to place rice papers automatically. Want to get a quick quote and consultant? Please click the button below and fill out the form.

How It Works

Specifications

| Model No. | RPS-24 | RPS-48 |

|---|---|---|

| Dimensions | Main machine: 8,600 (L) x 950 (W) x 1,400 (H) mm

Control box: 500 (L) x 270 (W) x 1,500 (H) mm |

Main machine: 8,600 (L) x 950 (W) x 1,400 (H) mm

Control box: 500 (L) x 270 (W) x 1,500 (H) mm |

| Power | 24 kW | 43 kW |

| Capacity | 1,200 - 1,500 pcs/hr (single line) | 2,400 - 3,000 pcs/hr (double line) |

| Conveyor belt size | 450 mm | 540 mm |

| Dia. of inlet pipe | 3/4 inch | |

| Weight (net) | 600 kg | 760 kg |

| Weight (gross) | 1,040 kg | 1,350 kg |

Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

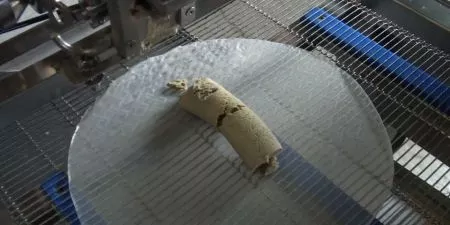

- Production Process: Setting rice paper (manual/automatic) -> Spraying water -> Absorbing excess water -> Steaming to soft -> Extruding filling -> Wrapping by hand

- Automatic sucking and setting rice paper devices are optional.

- Equipped with a water softener to prevent scale from building up in the pipes and clogging.

- The watering device is heated before spraying to save steaming time. The temperature of the heating device can be adjusted.

- The temperature and speed of the tunnel steamer is adjustable to facilitate controlling softness of rice papers.

- Equipped with a screw pump to enable filling to be extruded quantitatively and stably and remain intact. The amount of filling is adjustable.

Case Studies

Machinery Design for a South African Company

The client's businesses, establishing in South Africa, extend from producing frozen food, baking products to central kitchen and catering service.…

ANKO Spring Roll Production Line – Machinery Design for a Jordanian Company

At the end of Ramadan, fasting was not required. Thus, the client received a large number of spring roll orders…

For an Indian Machinery Design

The client is strict to control quality to ensure that consumers enjoy food with good quality and receive the best service…

Semi-Automatic Vegetarian Spring Roll Production Line – Machinery Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

Spring roll Production Line for Jordanian Company

How to determine the stickiness of stuffing which affect the depositor stability…

Cheese Spring Roll Automatic Equipment

Compare to Chinese spring roll, they are quite similar in the handmade production and crispy taste…

Machinery Design for a South African Company

The client's businesses, establishing in South Africa, extend from producing frozen food, baking products to central kitchen and catering service.…

ANKO Spring Roll Production Line – Machinery Design for a Jordanian Company

At the end of Ramadan, fasting was not required. Thus, the client received a large number of spring roll orders…

For an Indian Machinery Design

The client is strict to control quality to ensure that consumers enjoy food with good quality and receive the best service…

Semi-Automatic Vegetarian Spring Roll Production Line – Machinery Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

Spring roll Production Line for Jordanian Company

How to determine the stickiness of stuffing which affect the depositor stability…

Cheese Spring Roll Automatic Equipment

Compare to Chinese spring roll, they are quite similar in the handmade production and crispy taste…

- DownloadsBest Selling