Summer Roll

Your Summer Roll Production Planning And Summer Roll Recipe Consultant.

Model no : SOL-SRL-0-1

Summer Rolls are made with fresh ingredients, and they are a common and delightful dish in many Vietnamese restaurants. ANKO's commercial Summer Roll Machine has the capacity to make up to 1,500 Summer Rolls per hour; it automatically steams rice paper and extrudes portioned fillings onto the rice paper. The operator only needs to place the rice paper onto the conveyor and finish the rolling process by hand. An optional device is available to dispense the rice paper automatically, reducing labor costs. Click on the button below to complete the form and receive a preliminary quote. Our professional consultants will be pleased to assist you in determining the best solutions for your business.

About Summer Roll Production Solution

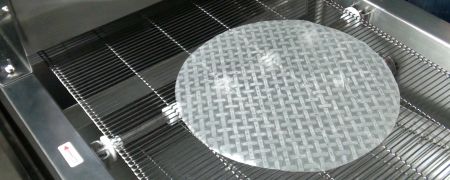

The rice paper's texture significantly affects the appearance and taste of a Summer Roll. ANKO's RPS Series Rice Paper Spring Roll Machine is designed with a sprinkler system and a drum to remove excess water before the rice paper enters the tunnel-type steamer. The rice paper's texture can be modified by adjusting the water temperature, duration of steaming, and the conveyor speed.

The filling system utilizes a screw pump to quantify and position the filling without over-processing the ingredients. The production line specifications can be customized to meet any client's requirements. This includes the option of a single production line with a capacity of 1,500 Rolls per hour or a double line with a productivity of 3,000 pieces per hour. This ANKO machine is perfect for large food factories, chain restaurants, central kitchens, and food processing plants.

1

Rolls / Wraps

- Sheeting / Wrapping

Case Studies

Automatic Spring Roll Production Line for a Canadian Company

The client runs chain restaurants and receives frozen food orders from supermarkets in Canada. Because of increasing demands…

Spring Roll Pastry Machinery Design For an Indian Company

The client is strict to control quality to ensure that consumers enjoy food with good quality and receive the best service. Due to business expansion…

Vegetarian Spring Roll Production Line Design for a German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to devote extra time on reprocessing…

Paneer Spring Roll Automatic Production Equipment Designed with Special Filling Device

Years ago, the client bought SR-24 spring roll machine from ANKO. This time, he placed another order because he trusts ANKO…

ANKO Spring Roll Machinery Design for a Jordanian Company

At the end of Ramadan, the client received a large number of spring roll orders. He uses three semi-automatic spring roll production machines…

Automatic Spring Roll Pastry Machinery Solved Labor Shortage for a South African Company

With the gourmet spring roll was getting more popular, insufficient employees could not meet higher demands…

Cheese Spring Roll Automatic Equipment Designed with a Customized Filling Mold

The company's cheese roll features its thin pastry made of batter. This time, through ANKO's customized services and trials…

Automatic Spring Roll Production Line for a Canadian Company

The client runs chain restaurants and receives frozen food orders from supermarkets in Canada. Because of increasing demands…

Spring Roll Pastry Machinery Design For an Indian Company

The client is strict to control quality to ensure that consumers enjoy food with good quality and receive the best service. Due to business expansion…

Vegetarian Spring Roll Production Line Design for a German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to devote extra time on reprocessing…

Paneer Spring Roll Automatic Production Equipment Designed with Special Filling Device

Years ago, the client bought SR-24 spring roll machine from ANKO. This time, he placed another order because he trusts ANKO…

ANKO Spring Roll Machinery Design for a Jordanian Company

At the end of Ramadan, the client received a large number of spring roll orders. He uses three semi-automatic spring roll production machines…

Automatic Spring Roll Pastry Machinery Solved Labor Shortage for a South African Company

With the gourmet spring roll was getting more popular, insufficient employees could not meet higher demands…

Cheese Spring Roll Automatic Equipment Designed with a Customized Filling Mold

The company's cheese roll features its thin pastry made of batter. This time, through ANKO's customized services and trials…

Automatic Spring Roll Production Line for a Canadian Company

The client runs chain restaurants and receives frozen food orders from supermarkets in Canada. Because of increasing demands…

The Best Selection - Get Started with Us to Discuss Your Needs

Vietnamese Rice Paper Spring Roll Machine

The RPS Series is designed with water spraying, steaming, softening, and filling devices, so workers only need to put rice papers on the conveyor and fold the spring rolls. You can also add a lifting device to place rice papers automatically. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More InfoSpecifications

Capacity:1,500 pcs/hr

Features

- Voltage can be designated.

- The thickness of summer roll wrapper and the amount of filling can be adjusted by parameter setting.

- The shape of summer roll can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- DownloadsBest SellingRelated Food Solutions Type