Palacsinta

Your Palacsinta Production Planning And Palacsinta Recipe Consultant.

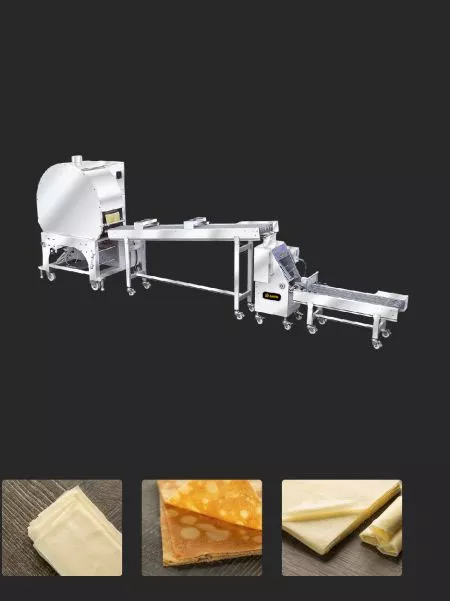

Model no : SOL-PLT-0-1

Hungarian pancakes (Palacsinta) can be served savory as a main dish or made into a sweet dessert. This national delicacy is a local staple and a must-try for visitors to Hungary. Palacsinta is usually found in restaurants or at food trucks, and it has great commercial opportunities with the continuing rise of the food delivery market. ANKO's SRP Automatic Wrapper Making machines have a production capacity of 2,700 pieces of square pastry sheets per hour, and by changing the batter formula, it can also produce a wide range of different Crepes and Wrappers. Want to get a quick quote and consultant? Please click the button below and fill out the form.

Customized Palacsinta Production Solutions

Palacsinta is said to be thinner than French Crêpes due to the addition of carbonated water or soda to the batter. ANKO SRP Automatic Wrapper Making machine can make great-tasting Palacsinta that are as thin as 0.4 millimeters. The automated process reduces required manual labor; it requires only one or two people to operate an entire production line and achieve high-volume output. ANKO has over 40 years of experience in the automated food machine industry, and we also offer customized Palacsinta production solutions based on specific product requirements.

Food's Gallery

1

Rolls / Wraps

- Palacsinta Forming

Palacsinta Forming

The quality and texture of the wrappers are crucial to a good Palacsinta, and the filling ingredients come second. ANKO's machines use standardized production procedures to ensure the Palacsinta are made into thin, soft pancakes with excellent elasticity and ensure consistency of the product weight and sizes.

Case Studies

For an Indian Machinery Design

The client is strict to control quality to ensure that consumers enjoy food with good quality and receive the best service. …

Machinery Design for a Spanish company

The company is well-known in Europe, mainly selling Chinese food. They always take client's health as priority…

Machinery Design for American Company

The company sells processing aquatic food products to all kinds of supermarkets in western countries. …

Machinery Design for a South African Company

The client's businesses, establishing in South Africa, extend from producing frozen food, baking products to central kitchen and catering service.…

Machinery Design for a Thai Company

The client has production lines for bakery and ethnic food, including baozi, siomay, hargao, bread, etc. In order…

For an Indian Machinery Design

The client is strict to control quality to ensure that consumers enjoy food with good quality and receive the best service. …

Machinery Design for a Spanish company

The company is well-known in Europe, mainly selling Chinese food. They always take client's health as priority…

Machinery Design for American Company

The company sells processing aquatic food products to all kinds of supermarkets in western countries. …

Machinery Design for a South African Company

The client's businesses, establishing in South Africa, extend from producing frozen food, baking products to central kitchen and catering service.…

Machinery Design for a Thai Company

The client has production lines for bakery and ethnic food, including baozi, siomay, hargao, bread, etc. In order…

For an Indian Machinery Design

The client is strict to control quality to ensure that consumers enjoy food with good quality and receive the best service. …

The Best Selection - Get Started with Us to Discuss Your Needs

Automatic Spring Roll and Samosa Pastry Sheet Machine

SRP Automatic Spring Roll and Samosa Pastry Sheet Machine is a food processing machine for automatically producing spring roll wrapper, samosa pastry, egg roll pastry, and even crepe. Simply prepare batter and the SRP Series will automatically finish the rest of steps, including baking, cutting, counting, and stacking. Finally, the baked pastries are nicely stacked in piles, ready to be packed, frozen, and sold at any time. It is also a samosa pastry machine. Samosa pastries can be made with the same process except that the way of cutting is different. Cutter can be customized as required. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More InfoSpecifications

Capacity: 2,700 pcs/hr

*Base on200 x 200 mm Palacsinta

Features

- Voltage can be designated.

- The thickness of palacsinta wrapper and the amount of filling can be adjusted by parameter setting.

- The shape of palacsinta can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- DownloadsBest SellingRelated Food Solutions Type