Forming Machine

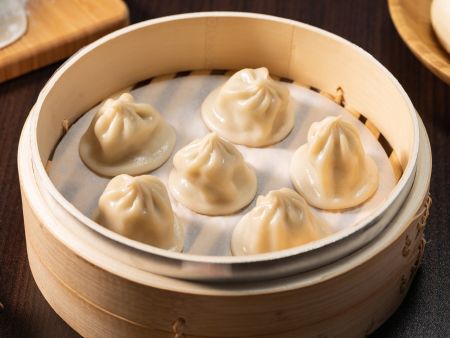

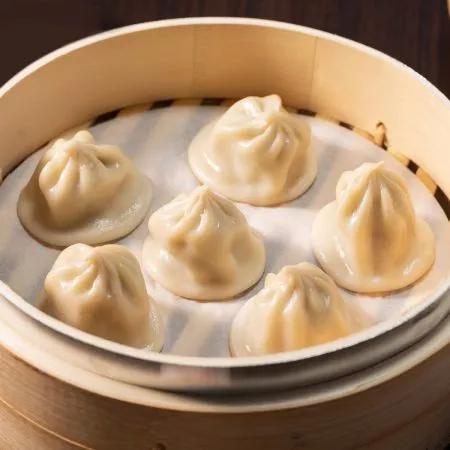

Mini Juicy Bun Maker

Model no : EA-100KA

The EA-100KA is a high-efficiency forming machine with an independent motor control system. The Forming Machine can work with HLT Series to produce various products such as mini juicy bun, meat bun, beef roll, baozi and the like with or without pleats. Its maximum capacity is up to 6,000 pieces per hour. Want to get a quick quote and consultant? Please click the button below and fill out the form.

How It Works

Food's Gallery

Optional Accessories

CE kitSpecifications

- Dimensions: 960 (L) x 510 (W) x 1,210 (H) mm

- Power: 0.48 kW

- Capacity: 6,000 pcs/hr

- Product weight: 10–80 g/pc

- Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

- Can connect to HLT Series or LP-3001 to make round products with or without filling.

- Can make a maximum of 12 pleats.

- Easy to assemble, clean, and maintain. All parts in contact with food are made of food-grade materials.

- Independent motor control system.

Case Studies

Automatic Layered Paratha Production Line for a Bangladeshi Company

The client decided to run a paratha production line due to the popularity of paratha. He trusted ANKO with Turnkey Planning Consulting Services…

Automatic Layer Paratha Production Line - Machinery Design for an Indian Company

The client contacted ANKO for food processing equipment solutions due to increasing demands. A total solution of Paratha…

Kompia Production Line to Solve the Demand Exceeds Supply

The owner's kompia is so delicious that people are willing to travel a long way to his store in a rural area. However, handmade kompias can't…

Multipurpose Filling & Forming Machine - Machinery Design for a Tunisian Company

The client is an owner of a hotel chain in Tunisia. Speaking of cooking, their insistence on food has gained favor with visitors…

Soup Dumping Automatic Production Equipment Designed to Solve Insufficient Capacity and Product Quality

The company owns a Cantonese restaurant serving handmade dim sum. With business growth, a lack of supply…

Xiao Long Bao Making Machine - Machinery Design for Dutch Company

The client started his business by opening a restaurant in Netherlands, serving dim sum dishes. He studied the Dutch flavor and healthy…

Additive-Free Dumpling Machinery Design for a Singaporean Company

A client and her partners started a business in Singapore. These entrepreneurs later decided to invest in the Chinese Dim Sum…

Automatic Layered Paratha Production Line for a Bangladeshi Company

The client decided to run a paratha production line due to the popularity of paratha. He trusted ANKO with Turnkey Planning Consulting Services…

Automatic Layer Paratha Production Line - Machinery Design for an Indian Company

The client contacted ANKO for food processing equipment solutions due to increasing demands. A total solution of Paratha…

Kompia Production Line to Solve the Demand Exceeds Supply

The owner's kompia is so delicious that people are willing to travel a long way to his store in a rural area. However, handmade kompias can't…

Multipurpose Filling & Forming Machine - Machinery Design for a Tunisian Company

The client is an owner of a hotel chain in Tunisia. Speaking of cooking, their insistence on food has gained favor with visitors…

Soup Dumping Automatic Production Equipment Designed to Solve Insufficient Capacity and Product Quality

The company owns a Cantonese restaurant serving handmade dim sum. With business growth, a lack of supply…

Xiao Long Bao Making Machine - Machinery Design for Dutch Company

The client started his business by opening a restaurant in Netherlands, serving dim sum dishes. He studied the Dutch flavor and healthy…

Additive-Free Dumpling Machinery Design for a Singaporean Company

A client and her partners started a business in Singapore. These entrepreneurs later decided to invest in the Chinese Dim Sum…

Automatic Layered Paratha Production Line for a Bangladeshi Company

The client decided to run a paratha production line due to the popularity of paratha. He trusted ANKO with Turnkey Planning Consulting Services…

Certification No.

- Russia Patent No.84540

- DownloadsBest Selling