Scallion pancake

Your Scallion pancake Production Planning And Scallion pancake Recipe Consultant.

Model no : SOL-SPC-0-1

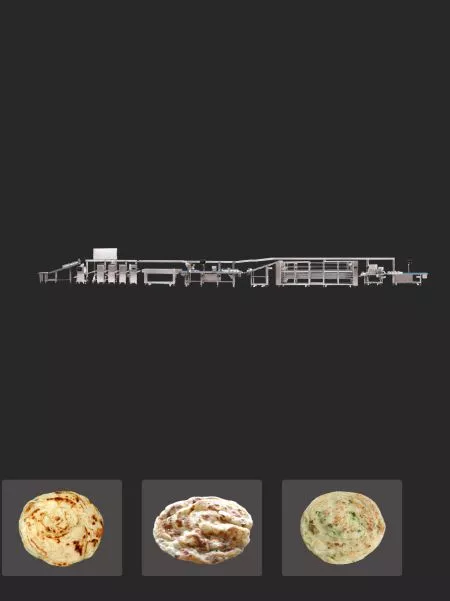

ANKO’s Scallion pancake production solution provides comprehensive consulting service and solves problems of production based on our years of experience, which enables you to automate production with less effort and stress. You can have one-stop shopping for not only Scallion pancake making machines, such as sieving, wrapper making, and packaging, but also your own proposal that is made ANKO’s sales engineers according to your production needs, factory layouts, existing equipment, human resources, etc. In the solution below, the machines can be adjusted in model and quantity according to real production needs. Want to get a quick quote and consultant? Please click the button below and fill out the form.

About Scallion pancake Production Solution

ANKO LP-3001 and LAP-5000 Lacha Paratha Machines are professionally designed to produce Scallion pancake and parathas; by adding the dough in the dough tank, the machine automatically folds in oil into the dough, and the patterned sprinkler then evenly sprinkles the chopped green scallion on top; the machine is designed to produce products with texture and taste similar to handmade products. And by adding the special designed pulling and folding device, the product line can produce lacha paratha. And by attaching ANKO PP-2 Automatic Filming and Pressing Machine, can form a continuous product line, suitable for mass production in large manufacturing facilities.

Food's Gallery

1

Rolls / Wraps

- Sheeting / Wrapping

Sheeting / Wrapping

ANKO’s Scallion Pancake Forming Machine is designed to process a variety of different filling ingredients and produce dough balls containing up to 32 layers at a capacity of 3,000 pieces per hour. This fully automated machine simulates handmade procedures to flatten the dough into a long dough sheet, then fold in il to be pressed which creates a multiple layered dough. The machine continues to fold, press, roll, and form dough balls that resemble handmade products.

Case Studies

Automatic Potsticker Machinery Design for a Taiwanese Company

Potsticker is popular in Great China area, so the supply was often unable to meet the demand. Thus, the client decided to manufacture with machine…

Automatic Wonton Machinery Design for a Canadian Company

With the growing number of branch stores, the client has to prepare more and more pieces of wonton every day. Therefore, they start to…

ANKO Spring Roll Production Line – Machinery Design for a Jordanian Company

At the end of Ramadan, fasting was not required. Thus, the client received a large number of spring roll orders…

Soup Dumping Automatic Production Equipment Designed to Solve Insufficient Capacity and Product Quality

The company owns a Cantonese restaurant serving handmade dim sum. With business growth, a lack of supply…

Green Scallion Pie Production Line Design for a Taiwanese Company

The client would like to save labor cost and increase productivity. He found ANKO to seek the best solution for keeping handmade taste...

Automatic Encrusting and Forming Machine - Machinery Design for Taiwanese Company

The client used to make their food products by hand. With more and more restaurants opened, the continuing growth in demand…

Additive-Free Dumpling Machinery Design for a Singaporean Company

A client and her partners started a business in Singapore. These entrepreneurs later decided to invest in the Chinese Dim Sum…

Automatic Potsticker Machinery Design for a Taiwanese Company

Potsticker is popular in Great China area, so the supply was often unable to meet the demand. Thus, the client decided to manufacture with machine…

Automatic Wonton Machinery Design for a Canadian Company

With the growing number of branch stores, the client has to prepare more and more pieces of wonton every day. Therefore, they start to…

ANKO Spring Roll Production Line – Machinery Design for a Jordanian Company

At the end of Ramadan, fasting was not required. Thus, the client received a large number of spring roll orders…

Soup Dumping Automatic Production Equipment Designed to Solve Insufficient Capacity and Product Quality

The company owns a Cantonese restaurant serving handmade dim sum. With business growth, a lack of supply…

Green Scallion Pie Production Line Design for a Taiwanese Company

The client would like to save labor cost and increase productivity. He found ANKO to seek the best solution for keeping handmade taste...

Automatic Encrusting and Forming Machine - Machinery Design for Taiwanese Company

The client used to make their food products by hand. With more and more restaurants opened, the continuing growth in demand…

Additive-Free Dumpling Machinery Design for a Singaporean Company

A client and her partners started a business in Singapore. These entrepreneurs later decided to invest in the Chinese Dim Sum…

Automatic Potsticker Machinery Design for a Taiwanese Company

Potsticker is popular in Great China area, so the supply was often unable to meet the demand. Thus, the client decided to manufacture with machine…

The Best Selection - Get Started with Us to Discuss Your Needs

Automatic Layer & Stuffed Paratha Production Line

LP-3001 is fully automatic to produce similar products such as paratha, pie and the like. Placing well-mixed dough and margarine into hoppers is the only thing to do. Then the fully automatic production processes include dough pressing, margarine extruding, the first folding and sheeting, the second folding and sheeting, rolling, cutting into balls, and pressing to form tasty products. When the production line equips a filling machine, LP-3001 can form various tastes of stuffed pastries, such as curry pastries, barbecued pork pastries, bean paste pastries, etc. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More Info Compare searies machineCompare with Similar Models

| Model no | Lacha Paratha and Green Scallion Pie Production Line LAP-5000 | Automatic Layer & Stuffed Paratha Production Line LP-3001 |

|---|---|---|

| Description | More efficient dough feeder | Special structure can make dough balls with up to 32 layers |

| Capacity | 2,100 - 6,300 pcs/hr | 3,000 pcs/hr |

| Weight | 50 - 130 g/pc | 40 - 130 g/pc |

| More Info | More Info |

Specifications

Capacity: 3,000 pcs/hr or 300 kg/hr

Features

- Voltage can be designated.

- The thickness of scallion pancake wrapper and the amount of filling can be adjusted by parameter setting.

- The shape of scallion pancake can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- DownloadsBest SellingRelated Food Solutions Type