Blini

Blini Machine and Production Solutions

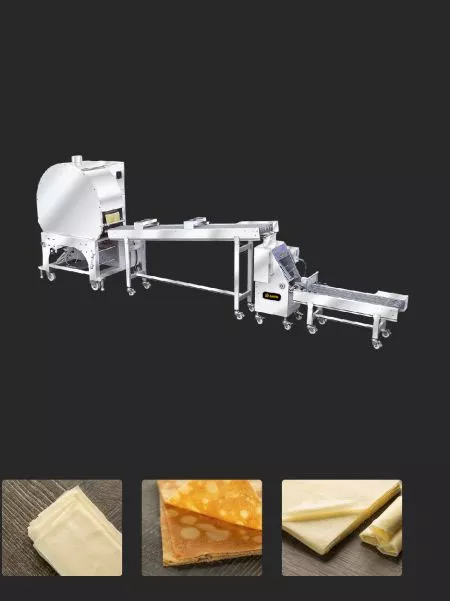

Model no : SOL-BLN-0-1

Blini is commonly consumed in European countries. Blini has recently become a very popular ready-to-eat product found in supermarkets, convenience stores, and sold online.

ANKO’s Blini Machinery has the capacity of producing 2,000 pc/hr. with minimal labor costs. In the solution below, the machines can be adjusted in model and quantity according to real production needs. Want to get a quick quote and consultant? Please click the button below and fill out the form.

Customize a Blini Production Solution for your Needs

ANKO has more than 45 years of experience in the Food Machinery business. We manufacture the equipment you need for an automated blini production line, and ANKO also offer services in finding dough mixers, filling and wrapping devices, and packaging machines all to help create a customized production line for you. ANKO’s machines help reduce the expenses of the human resources usually required for Blini manufacturing. Additionally, ANKO has a team of food experts to assist you with recipe development, consultancy, and refinements to achieve the best tasting products.

1

Rolls / Wraps

- Sheeting / Wrapping

Sheeting / Wrapping

ANKO’s Blini Machine can produce standard blinis with the radius of 40 mm and 100 mm; in addition, the parameter settings can be adjusted for customized recipes. The machine is equipped with a special extruding device which can produce stuffed blinis with a handmade appearance, including manufacturing the well-liked sweet blinis which are often filled with blueberry jam or apple sauce.

Case Studies

Dumpling Equipment Designed to Enhance a Food's Handmade Look

Sometimes machine-made dumplings cannot meet client's required shape. Thus, ANKO designed handmade pleats…

Dumpling Machine Helps to Increase Capacity and Standardize Products

Consumers really liked the handmade dumplings, but "sold out" was the most important issue with which the company had to deal…

Burrito Production Equipment Designed with Unique Folding Device

Compared to spring roll wrapper, tortilla is thicker and harder. Therefore, ANKO couldn't fold burrito with the folding device of…

Xiao Long Bao Making Machine - Machinery Design for Dutch Company

The client started his business by opening a restaurant in Netherlands, serving dim sum dishes. He studied the Dutch flavor and healthy…

Semi-Automatic Blini Production Equipment Designed with Soft Pancake Stacker

Our agent gave a test run with ANKO's SRP for making blini, but failed to arrange them in a pile. Thus, ANKO's engineers developed…

Multipurpose Filling & Forming Machine - Machinery Design for a Tunisian Company

The client is an owner of a hotel chain in Tunisia. Speaking of cooking, their insistence on food has gained favor with visitors…

Semi-Automatic Vegetarian Spring Roll Production Line - Machinery Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

Dumpling Equipment Designed to Enhance a Food's Handmade Look

Sometimes machine-made dumplings cannot meet client's required shape. Thus, ANKO designed handmade pleats…

Dumpling Machine Helps to Increase Capacity and Standardize Products

Consumers really liked the handmade dumplings, but "sold out" was the most important issue with which the company had to deal…

Burrito Production Equipment Designed with Unique Folding Device

Compared to spring roll wrapper, tortilla is thicker and harder. Therefore, ANKO couldn't fold burrito with the folding device of…

Xiao Long Bao Making Machine - Machinery Design for Dutch Company

The client started his business by opening a restaurant in Netherlands, serving dim sum dishes. He studied the Dutch flavor and healthy…

Semi-Automatic Blini Production Equipment Designed with Soft Pancake Stacker

Our agent gave a test run with ANKO's SRP for making blini, but failed to arrange them in a pile. Thus, ANKO's engineers developed…

Multipurpose Filling & Forming Machine - Machinery Design for a Tunisian Company

The client is an owner of a hotel chain in Tunisia. Speaking of cooking, their insistence on food has gained favor with visitors…

Semi-Automatic Vegetarian Spring Roll Production Line - Machinery Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

Dumpling Equipment Designed to Enhance a Food's Handmade Look

Sometimes machine-made dumplings cannot meet client's required shape. Thus, ANKO designed handmade pleats…

The Best Selection - Get Started with Us to Discuss Your Needs

Blini Production Line

ANKO's Blini Production Line can automatically produce delicious blini. The stable depositor feeds equal portions of filling. Both weight and size of product are able to be controlled. With our production line, the texture of the products is unspoiled and competitive with handmade ones. We assure you of high quality and professional machines. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More Info Compare searies machineCompare with Similar Models

| Model no | Blini Production Line BN-24 | Automatic Spring Roll and Samosa Pastry Sheet Machine SRP Series |

|---|---|---|

| Description | Can be adjusted the product size and filling | High capacity and uniform products |

| Capacity | Max. 2,000 pcs/hr (based on pastry length of 240 mm) | 2,700 pcs/hr, 9 m/min (200 x 200 mm) |

| Weight | 75 - 80 g/pc | - |

| More Info | More Info |

Specifications

Capacity: 2000 pcs/hr

Features

- Voltage can be designated.

- The thickness of blini wrapper and the amount of filling can be adjusted by parameter setting.

- The shape of blini can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- DownloadsBest SellingRelated Food Solutions Type