Quesadilla Making Machine

Quesadilla Making Machine

Model no : QS-2000

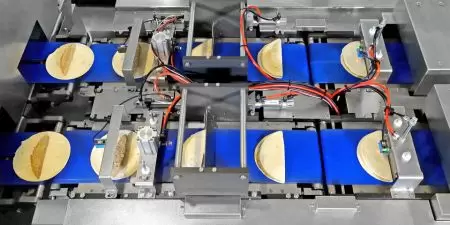

The world's first automated Quesadilla Making Machine is officially available! Say goodbye to time-consuming and inefficient hand production. ANKO’s QS-2000 Quesadilla Making Machine is designed with a dual-line system, capable of producing up to 2,000 Quesadillas per hour. Simply place the tortillas on the conveyor, and the machine will automatically fill, fold, press, and form the Quesadillas. It is suitable for small to medium-sized food factories, central kitchens, restaurants, and catering businesses. The exclusive pressing mechanism enables fast and effective Quesadilla forming, ensuring the fillings are evenly distributed with great consistency. This innovative filling system can process various ingredients such as chicken, beef, vegetable with cheeses, while preserving their original textures. The machine can produce 5 to 6-inch Quesadillas, achieving stable and high-quality automated production. ANKO can also customize the machine to meet specific product requirements. Click the button below and fill out the form and receive a preliminary quote. Our professional consultants will provide you with the most effective production solutions.

How It Works

Food's Gallery

Specifications

- Min. space required: 3,260 (L) x 1,300 (W) x 1,920 (H) mm

- Power: 2.4 kW

- Capacity: 2,000 pcs/hr

- Product dimension: 125–153 (L) x 62–77 (W) x 9.5–13 (H) mm

- Suggested wrapper size (Dia.): 5–6 inches

- Product weight: 42–75 g (varies depending on ingredient of filling)

- Filling hopper capacity: 60 L

- Air consumption: 220 L/min (@ 5 kg/cm^2)

- Weight (net): 1,200 kg

- Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

-

Exclusive Pressing Design

Two roller drums press on each Quesadilla to ensure the filling is evenly distributed on the Tortillas, so the final products are formed symmetrically and each bite taste great.

-

Unique Filling System

It can smoothly process most filling ingredients up to 5mm pieces in diameter, such as chicken, beef, vegetables, and cheeses, etc. Each Quesadilla contains 25 to 40 grams of fillings.

-

Automatic Detecting Device to Activate Production

The machine can process 5 to 6-inch Tortillas, and it features an automatic safety sensor, which activates the production process only after the Tortilla is in place.

-

Customizable Folding Molds

ANKO can provide corresponding folding molds and accessories to realize mass production according to customer product specifications.

-

Double-line Production Design

It can operate as a single-line or a dual-line production, with a maximum capacity of 2,000 Quesadillas per hour.

Case Studies

Tailormade for Quesadilla Production! ANKO QS-2000 Solves Many Issues Relate to Labor Shortages and Production Insufficiency

Exclusive Roller Design combines experience and technology to ensure Quesadillas are evenly filled…

ANKO redesigned our Burrito Machine's Folding Mechanism and provided great solutions for a US Client

Compared to spring roll wrapper, tortilla is thicker and harder. Thus, ANKO designed a special pressing and fixing device to prevent…

ANKO's Semi-Automatic Burrito Forming Machine Design Helped Increased a US Company's Productivity

When making burrito by hand, the employees may scoop different amounts of stuffing. Thus, ANKO designed the machine is fully controlled by parameter…

Tailormade for Quesadilla Production! ANKO QS-2000 Solves Many Issues Relate to Labor Shortages and Production Insufficiency

Exclusive Roller Design combines experience and technology to ensure Quesadillas are evenly filled…

ANKO redesigned our Burrito Machine's Folding Mechanism and provided great solutions for a US Client

Compared to spring roll wrapper, tortilla is thicker and harder. Thus, ANKO designed a special pressing and fixing device to prevent…

ANKO's Semi-Automatic Burrito Forming Machine Design Helped Increased a US Company's Productivity

When making burrito by hand, the employees may scoop different amounts of stuffing. Thus, ANKO designed the machine is fully controlled by parameter…

Tailormade for Quesadilla Production! ANKO QS-2000 Solves Many Issues Relate to Labor Shortages and Production Insufficiency

Exclusive Roller Design combines experience and technology to ensure Quesadillas are evenly filled…

ANKO redesigned our Burrito Machine's Folding Mechanism and provided great solutions for a US Client

Compared to spring roll wrapper, tortilla is thicker and harder. Thus, ANKO designed a special pressing and fixing device to prevent…

ANKO's Semi-Automatic Burrito Forming Machine Design Helped Increased a US Company's Productivity

When making burrito by hand, the employees may scoop different amounts of stuffing. Thus, ANKO designed the machine is fully controlled by parameter…

- DownloadsBest Selling