Quesadilla

Quesadilla Machine and Production Solutions

Model no : SOL-QSA-0-1

Quesadillas are a classic Mexican dish made with Tortillas, cheeses, and various delicious fillings. ANKO's QS-2000 Quesadilla Making Machine has a highly efficient capacity to produce 2,000 pieces per hour. It can also handle a wide variety of ingredients, such as chicken, pork, beef, seafood, and vegetables. This machine automatically extrudes filling onto each Tortilla, folds, and presses the ingredients to create perfectly formed Quesadillas. The push-block filling system prevents the deformation and squishing of ingredients like green peas and bacon pieces from retaining their original textures during mechanical production. ANKO also provides comprehensive pre-sales and after-sales services to ensure the quality and production quantity of the Quesadillas. Click the button below to complete the form and receive an initial quotation; our professional consultants will further assist you.

Quesadilla machine provides customizable solutions for increasing production efficiency

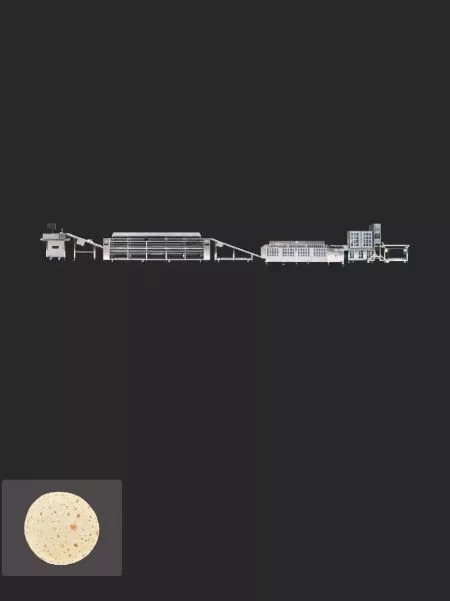

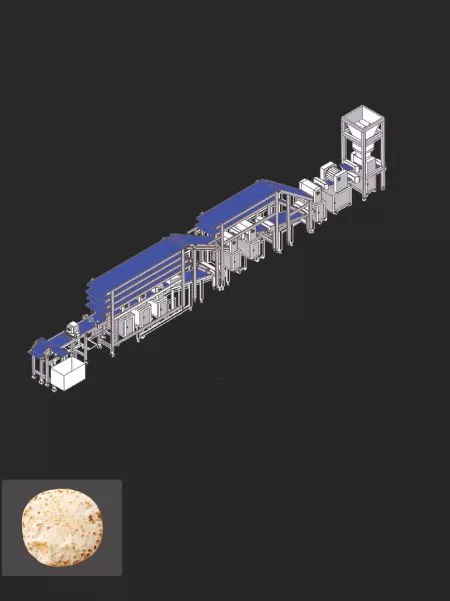

After years of development, ANKO has launched the world's first Quesadilla Making Machine to lower manual labor costs, improve production efficiency, and effectively reduce overall operational costs. ANKO also provides one-stop solutions to configure automated Tortilla machines and packaging equipment to complete a customized Quesadilla production line.

First, select a Tortilla production line based on your specific production requirements. Then ANKO QS-2000 Quesadilla Making machine will automatically extrude portioned filling ingredients onto each Tortilla and fold it in half. Next, a unique dual-roller mechanism rapidly spreads the fillings evenly on the Tortilla to create perfect 5–6 inch Quesadillas. This dual production line can operate independently, and the machine can be outfitted with an automatic packaging machine or freezing equipment for retail purposes. ANKO's machine meets the various product demands of small to medium-sized food factories, central kitchens, restaurants, and catering businesses.

Customization is the primary feature of this machine. ANKO can customize the size, width, thickness, and weight of the Quesadillas to meet our client's specific product requirements. ANKO's automated food machines are manufactured with strict hygienic standards, are easy to operate and maintain, and are perfect for producing delicious Quesadillas with great efficiency and consistency. We also provide supplemental recipe consultation, factory planning, configuration services, and prompt and comprehensive after-sales support to assist you with your Quesadilla production.

Food's Gallery

1

Rolls / Wraps

- Sheeting / Wrapping

Sheeting / Wrapping

This machine can process 5 to 6-inch Tortillas; the two adjustable pressing rollers can handle different types of filling ingredients, and either tightly pack or loosely press the filled Tortillas into Quesadillas. ANKO’s automatic Quesadilla Production Line is customizable to meet specific product requirements, and we provide recipe optimization, and comprehensive before and after-sales services to ensure the success of your business.

Case Studies

ANKO's Semi-Automatic Burrito Forming Machine Design Helped Increased a US Company's Productivity

When making burrito by hand, the employees may scoop different amounts of stuffing. Thus, ANKO designed the machine is fully controlled by parameter…

Croquetas (Croquette) Automatic Production Line Design for an Indonesia Company

An ANKO client having had a successful food business in Colombia selling croquetas (croquette) to casinos and other retailers…

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

The NDL-100 Commercial Noodle Machine produces different types of noodles by simply changing the molds, such as Spaghetti, Ramen Noodles and…

ANKO Developed New Sweet Spring Rolls for a US Client to Resolve Production Issues of Fillings

As the demand for spring rolls has continued to increase, the customer learned about ANKO's latest SR-27 Spring Roll Machine…

Tailormade for Quesadilla Production! ANKO QS-2000 Solves Many Issues Relate to Labor Shortages and Production Insufficiency

Exclusive Roller Design combines experience and technology to ensure Quesadillas are evenly filled…

ANKO redesigned our Burrito Machine's Folding Mechanism and provided great solutions for a US Client

Compared to spring roll wrapper, tortilla is thicker and harder. Thus, ANKO designed a special pressing and fixing device to prevent…

EMP-900 Machine – Designed for producing Empanadas made with high fat content dough

ANKO has been approached by many companies and clients seeking a machine that can process high fat content dough…

ANKO's Semi-Automatic Burrito Forming Machine Design Helped Increased a US Company's Productivity

When making burrito by hand, the employees may scoop different amounts of stuffing. Thus, ANKO designed the machine is fully controlled by parameter…

Croquetas (Croquette) Automatic Production Line Design for an Indonesia Company

An ANKO client having had a successful food business in Colombia selling croquetas (croquette) to casinos and other retailers…

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

The NDL-100 Commercial Noodle Machine produces different types of noodles by simply changing the molds, such as Spaghetti, Ramen Noodles and…

ANKO Developed New Sweet Spring Rolls for a US Client to Resolve Production Issues of Fillings

As the demand for spring rolls has continued to increase, the customer learned about ANKO's latest SR-27 Spring Roll Machine…

Tailormade for Quesadilla Production! ANKO QS-2000 Solves Many Issues Relate to Labor Shortages and Production Insufficiency

Exclusive Roller Design combines experience and technology to ensure Quesadillas are evenly filled…

ANKO redesigned our Burrito Machine's Folding Mechanism and provided great solutions for a US Client

Compared to spring roll wrapper, tortilla is thicker and harder. Thus, ANKO designed a special pressing and fixing device to prevent…

EMP-900 Machine – Designed for producing Empanadas made with high fat content dough

ANKO has been approached by many companies and clients seeking a machine that can process high fat content dough…

ANKO's Semi-Automatic Burrito Forming Machine Design Helped Increased a US Company's Productivity

When making burrito by hand, the employees may scoop different amounts of stuffing. Thus, ANKO designed the machine is fully controlled by parameter…

The Best Selection - Get Started with Us to Discuss Your Needs

Quesadilla Making Machine

The world's first automated Quesadilla Making Machine is officially available! Say goodbye to time-consuming and inefficient hand production. ANKO’s QS-2000 Quesadilla Making Machine is designed with a dual-line system, capable of producing up to 2,000 Quesadillas per hour. Simply place the tortillas on the conveyor, and the machine will automatically fill, fold, press, and form the Quesadillas. It is suitable for small to medium-sized food factories, central kitchens, restaurants, and catering businesses. The exclusive pressing mechanism enables fast and effective Quesadilla forming, ensuring the fillings are evenly distributed with great consistency. This innovative filling system can process various ingredients such as chicken, beef, vegetable with cheeses, while preserving their original textures. The machine can produce 5 to 6-inch Quesadillas, achieving stable and high-quality automated production. ANKO can also customize the machine to meet specific product requirements. Click the button below and fill out the form and receive a preliminary quote. Our professional consultants will provide you with the most effective production solutions.

More Info Compare searies machineCompare with Similar Models

Specifications

Capacity: 2,000 pcs/hr

Features

- Voltage can be designated.

- The thicknesses of quesadilla can be adjusted by parameter setting.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- DownloadsBest SellingRelated Food Solutions Type