Cigar roll

Your Cigar roll Production Planning And Cigar roll Recipe Consultant.

Model no : SOL-CGR-0-1

Cigar Rolls are delicious Spring Rolls made into delicate bite sizes, making them the perfect appetizer and finger food to serve at events and gatherings before the main meal. A Lumpia Shanghai business in the Philippines branded out to the world with great success; they opened retail stores in Hong Kong, Japan, the United States, and many countries in Southeast Asia. ANKO recognized the enormous potential of the Global Spring Roll market. Therefore, we developed automated machines that produce Cigar Spring Rolls filled with various ingredients such as chicken, cheese, and vegetables. ANKO’s machines can also produce Spring Rolls, Egg Rolls, and Lumpia Shanghai, providing the advantages needed to succeed in the competitive Spring Roll Market.

Optimized and Customized Cigar Spring Roll Production

Spring Rolls are a popular party snack. Varieties include Chinese Spring Rolls, Vegan Cigar Spring Rolls, Turkish Cheese and Herb Cigars, Moroccan Meat Cigars, Cheese Spring Rolls, Sweet Spring Rolls, and Chocolate Spring Rolls. To increase productivity and reduce labor, ANKO recommends our semi-automatic Spring Roll equipment for producing smaller-sized open-end and sealed Cigar Spring Rolls.

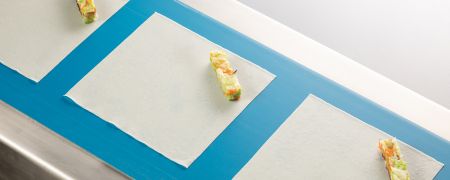

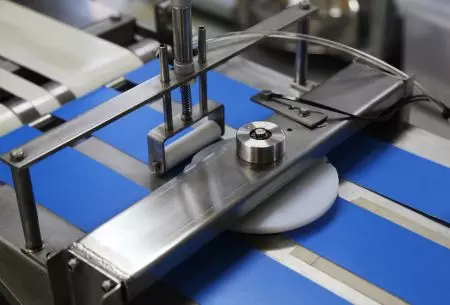

ANKO SRPF Series Semi-Automatic Spring Roll and Samosa Production Line includes a pastry sheet maker, a filling system, a conveyor belt, and a worktable for completing the manual folding process. The pastry maker can produce Spring Roll Wrappers, Samosa Wrappers, Egg Roll Wrappers, and Crepe Sheets; the filling system can process various ingredients. The entire automated process begins with baking the wrapper sheets made from pre-mixed batter, dividing the wrappers, and extruding filling onto the Spring Roll wrappers. Then, the product is completed by manual forming.

Additionally, ANKO can provide you with implemented Cigar Spring Roll Production Solutions, including machine configuration at different food preparation and processing stages. ANKO also has our in-house “Food Lab,” an industry first to provide professional recipe consultation services to ensure the Cigar Spring Rolls are made with great texture and taste, just like they were handmade.

Food's Gallery

1

Rolls / Wraps

- Sheeting / Wrapping

Sheeting / Wrapping

ANKO’s Cigar Spring Roll Machine can produce products from 30 to 80 grams per piece at a capacity of 2,400 pieces per hour. The thickness of the wrappers can be adjusted from 0.4 to 0.8 mm, and the type of filling ingredients and the length of the final products can be changed, all to meet your specific Cigar Spring Roll requirements.

Case Studies

Cheese Spring Roll Automatic Equipment Designed with a Customized Filling Mold

This cooperation is not the first time. The client had bought our machine before and was satisfied with quality and productivity…

Spring roll Production Line for a Jordanian Company

The client purchased our HLT-series, PP-2, SD-97, SRP, and Maammoul Production Line, full of confidence in ANKO's machines. This time, he decided to buy…

Paneer Spring Roll Automatic Production Equipment Designed with Special Filling Device

Years ago, the client bought SR-24 spring roll machine from ANKO. This time, he placed another order because he trusts ANKO…

Spring Roll Pastry Machinery Design to Solve Labor Shortage for a South African Company

The client was seeking a food machine supplier possessing high quality machines and professional services. They heard ANKO…

Semi-Automatic Vegetarian Spring Roll Production Line – Machinery Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

Spring Roll Production Line to Expand Production for a Canadian Company

The client runs chain restaurants and receives frozen food orders from supermarkets in Canada. Because of increasing demands, they purchased machine from ANKO…

Spring Roll Production Line to Improve Product Quality for an American Company

Since client's business grew, he would like to increase productivity and improve the looks of products. He had been looking for a solution…

Cheese Spring Roll Automatic Equipment Designed with a Customized Filling Mold

This cooperation is not the first time. The client had bought our machine before and was satisfied with quality and productivity…

Spring roll Production Line for a Jordanian Company

The client purchased our HLT-series, PP-2, SD-97, SRP, and Maammoul Production Line, full of confidence in ANKO's machines. This time, he decided to buy…

Paneer Spring Roll Automatic Production Equipment Designed with Special Filling Device

Years ago, the client bought SR-24 spring roll machine from ANKO. This time, he placed another order because he trusts ANKO…

Spring Roll Pastry Machinery Design to Solve Labor Shortage for a South African Company

The client was seeking a food machine supplier possessing high quality machines and professional services. They heard ANKO…

Semi-Automatic Vegetarian Spring Roll Production Line – Machinery Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

Spring Roll Production Line to Expand Production for a Canadian Company

The client runs chain restaurants and receives frozen food orders from supermarkets in Canada. Because of increasing demands, they purchased machine from ANKO…

Spring Roll Production Line to Improve Product Quality for an American Company

Since client's business grew, he would like to increase productivity and improve the looks of products. He had been looking for a solution…

Cheese Spring Roll Automatic Equipment Designed with a Customized Filling Mold

This cooperation is not the first time. The client had bought our machine before and was satisfied with quality and productivity…

The Best Selection - Get Started with Us to Discuss Your Needs

Semi-Automatic Spring Roll and Samosa Production Line

The Semi-Automatic Spring Roll and Samosa Production Line consists of a pastry making machine, a filling depositor, and a conveyor with working table for manual wrapping. The pastry making machine can produce spring roll pastry, samosa pastry, egg roll pastry, and even crepe, and the filling depositor can work well with a wide variety of filling. After pouring batter and filling in hoppers, the production line automatically bakes batter, cuts pastries, and deposits required amount of filling, and then workers can wrap spring rolls on the conveyor's working table. Moreover, the machine can connect with stacking machine to stack pastries alone for selling. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More Info Compare searies machineCompare with Similar Models

Specifications

Capacity: 2,400 pcs/hr

*Base on200 x 200 mm Cigar-roll

Features

- Voltage can be designated.

- The thickness of cigar roll wrapper and the amount of filling can be adjusted by parameter setting.

- The shape of cigar roll can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- DownloadsBest SellingRelated Food Solutions Type