Arabic Bread

Arabic Bread Machinery and Production Solutions.

Model no : SOL-ABD-0-1

Arabic bread or Pita bread is a type of leavened flatbread, it’s commonly served with hummus and other dips, and it can be filled with various other ingredients making it into a pocket sandwich.

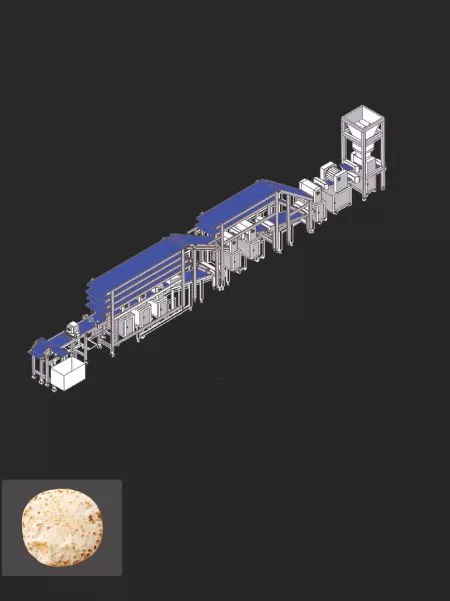

The demand for Arabic breads has drastically increased in recent years and this has created great business opportunities all over the World. ANKO’s Arabic Bread production line is designed for medium to large scale food factories and the automated production has the capacity of producing 6,000 pc/hour. ANKO’s machine is highly efficient and the ideal manufacturing solution to help save labor costs and increase productivity. Want to get a quick quote and consultant? Please click the button below and fill out the form.

ANKO is the solution for Your customized Arabic Bread Production Line

ANKO has more than 45 years of Food Machine manufacturing experience and not only do we offer professional equipment for Arabic Bread Manufacturing, but we can also provide you with dough mixers, packaging machines, and consultation all to help implement your production line.

1

Rolls / Wraps

- Sheeting / Wrapping

Sheeting / Wrapping

ANKO’s Arabic Bread production line is equipped with a unique pressing device to produce evenly round flatbreads in many different sizes. The texture and consistency of the machine-made bread after freezing and reheating is similar to a fresh handmade bread. ANKO’s production process is easy to monitor, efficient, and can be effort managed.

Case Studies

Automatic Samosa Pastry Sheet Machine– Machinery Design for Kuwait Company

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one…

Sambousek Automatic Production Equipment Designed with a Customized Half-moon Rotary Mold

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products…

Pineapple Cake Automatic Production Line Set up for New Product Launch

The client found that Taiwanese pineapple cake is very popular and delicious, so he decided to produce pineapple cakes and sell…

Kubba Automatic Production Equipment Designed to Solve the Forming Problem Caused by Sticky Crust

The production demand has increased since the client sold products in multi-channel. Thus, he was looking for an expert of food machine…

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

Automatic Layered Paratha Production Line for a Bangladeshi Company

The client decided to run a paratha production line due to the popularity of paratha. He trusted ANKO with Turnkey Planning Consulting Services…

Kibbi Mosul Pastry Production Line Design for a Jordanian Company

Many Middle Eastern immigrants in western countries cannot forget the taste of hometown. Therefore, ANKO designed Kibbi Mosul Pastry Production Line…

Automatic Samosa Pastry Sheet Machine– Machinery Design for Kuwait Company

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one…

Sambousek Automatic Production Equipment Designed with a Customized Half-moon Rotary Mold

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products…

Pineapple Cake Automatic Production Line Set up for New Product Launch

The client found that Taiwanese pineapple cake is very popular and delicious, so he decided to produce pineapple cakes and sell…

Kubba Automatic Production Equipment Designed to Solve the Forming Problem Caused by Sticky Crust

The production demand has increased since the client sold products in multi-channel. Thus, he was looking for an expert of food machine…

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

Automatic Layered Paratha Production Line for a Bangladeshi Company

The client decided to run a paratha production line due to the popularity of paratha. He trusted ANKO with Turnkey Planning Consulting Services…

Kibbi Mosul Pastry Production Line Design for a Jordanian Company

Many Middle Eastern immigrants in western countries cannot forget the taste of hometown. Therefore, ANKO designed Kibbi Mosul Pastry Production Line…

Automatic Samosa Pastry Sheet Machine– Machinery Design for Kuwait Company

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one…

The Best Selection - Get Started with Us to Discuss Your Needs

Pita Bread Making Machine

Pita Bread Making Machine includes the processes of cutting and sheeting and a unique layered resting conveyor that shortens the dough resting time. The machine design is similar to the manual production processes, which is our aim to produce products that keep artisanal characters. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More Info Compare searies machineCompare with Similar Models

| Model no | Automatic Encrusting and Forming Machine SD-97L | Automatic Table-Type Encrusting and Forming Machine SD-97SS | Automatic Encrusting and Forming Machine SD-97W |

|---|---|---|---|

| Description | Max. product weight up to 200 grams | Most compact machine | Two color wrapper is available |

| Capacity | 2,400 - 4,800 pcs/hr | 600 - 3,600 pcs/hr | 1,000 - 4,000 pcs/hr |

| Weight | 40 - 200 g/pc | 10 - 60 g/pc | 10 - 70 g/pc |

| More Info | More Info | More Info |

Specifications

Capacity: 6,000 pcs/hr or 500 kg/hr

Features

- Voltage can be designated.

- The thickness of arabic bread wrapper and the amount of filling can be adjusted by parameter setting.

- The shape of arabic bread can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- DownloadsBest SellingRelated Food Solutions Type