Spring Roll Production Line

Spring Roll Machine

Model no : SR-24

Discontinued Models

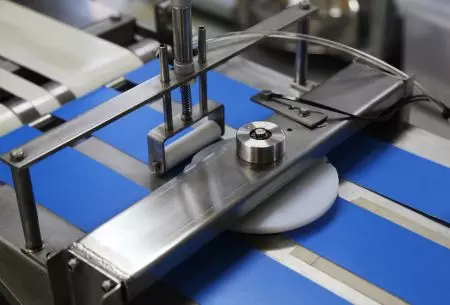

The spring roll machine designed by ANKO is fully automatic to produce 2,400 spring rolls in one hour. After pouring well-stirred batter and filling, the automatic process starts from baking drum, cooling fans, cutter with a sensor to innovative rotating, depositing, folding and rolling devices. The Spring roll Production Line is the ideal solution for making identical quality and tasty spring rolls that can compete with handmade ones. Want to get a quick quote and consultant? Please click the button below and fill out the form.

How It Works

Food's Gallery

Specifications

- Min. space required: 7,500 (L) x 1,300 (W) x 2,200 (H) mm

- Power: 38 kW

- Capacity: 2,400 pcs/hr

- Product dimension: 25–30 (Dia.) x 100 (L) mm

- Product weight: 40–50 g (varies depending on ingredient of filling)

- Air consumption: 480 L/min (@ 6 kg/cm^2)

- Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Features

- Reasonable price.

- Easy to clean, repair and maintain.

- The wrapping device is designed according to the manual wrapping process to roll up every spring roll firmly. After frying, the spring roll is crispy but not oily.

-

New special depositor can smoothly deposit different fillings such asVegetable filling : The new depositing design can process up to 20x20mm cooked leaf vegetables and 5-8mm cube cooked root vegetables to keep the best taste and texture of filling. Also, the depositor is equipped with a unique filter which can extract excessive liquid from filling and dispense with the need for extra dehydration process.Mixed vegetable and meat filling : The max. size of diced meat can be up to 10mm cube. The proper ratio of meat to vegetable is 1 to 2.Pure meat filling : Diced meat can be up to 10mm cube, the popular stir fried loose beef filling in Gulf countries can be deposited and wrapped hassle free.Mixed bean sprout, meat, and vegetable filling : The proper ratio of bean sprout and vegetable to beef is 2 to 1. This type of filling is especially popular in the Netherlands.

Case Studies

Cheese Spring Roll Automatic Equipment

Compare to Chinese spring roll, they are quite similar in the handmade production and crispy taste…

Spring roll Production Line for Jordanian Company

How to determine the stickiness of stuffing which affect the depositor stability…

Paneer Spring Roll Automatic Equipment

High moisture content in the filling affected machine operation.…

Semi-Automatic Vegetarian Spring Roll Production Line – Machinery Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

Spring Roll Production Line for a Canadian Company

In Canada, the frozen food market is in the keen competition…

Spring Roll Production Line for American Company

ANKO have abundant knowledge in food ingredients and recipes…

Cheese Spring Roll Automatic Equipment

Compare to Chinese spring roll, they are quite similar in the handmade production and crispy taste…

Spring roll Production Line for Jordanian Company

How to determine the stickiness of stuffing which affect the depositor stability…

Paneer Spring Roll Automatic Equipment

High moisture content in the filling affected machine operation.…

Semi-Automatic Vegetarian Spring Roll Production Line – Machinery Design for German Company

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to…

Spring Roll Production Line for a Canadian Company

In Canada, the frozen food market is in the keen competition…

Spring Roll Production Line for American Company

ANKO have abundant knowledge in food ingredients and recipes…

Certification No.

- Taiwan Patent No.: I391097, M457429

- USA Patent No.: US 8,505,445, US 7,963,216

- China Patent No.: ZL 2006 2 0148890.1

- Italy Patent No.: 0000266110

- Best Selling