Pizza Base

Your Pizza Base Production Planning And Pizza Base Recipe Consultant.

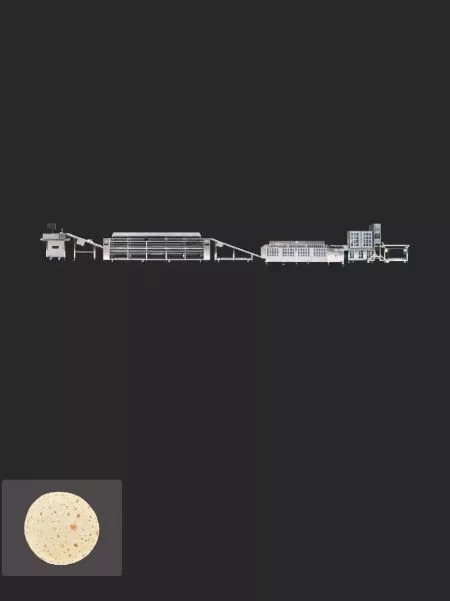

Model no : SOL-PZB-0-1

ANKO’s Pizza Base production solution provides comprehensive consulting service and solves problems of production based on our years of experience, which enables you to automate production with less effort and stress. You can have one-stop shopping for not only Pizza Base making machines, such as sieving, wrapper making, and packaging, but also your own proposal that is made ANKO’s sales engineers according to your production needs, factory layouts, existing equipment, human resources, etc. In the solution below, the machines can be adjusted in model and quantity according to real production needs. Want to get a quick quote and consultant? Please click the button below and fill out the form.

1

Rolls / Wraps

- Sheeting / Wrapping

Sheeting / Wrapping

The size and thickness of a Pizza can be tailored to your specifications. By changing the roller cutter, ANKO’s machine can produce Pizzas that range in size from 18cm to 30cm in diameter, and the thickness can vary from 1mm-3mm. ANKO’s Automated Pizza production line is customizable, and we also provide recipe consultation services to help you be more successful in your business.

Case Studies

Shrimp Spring Roll Pastry Machinery Design for an American Company

As for spring roll pastry import, high cost and quality degradation caused by rising temperature during shipping prompted the client to purchase a machine…

Calzone Automatic Production Machinery Design for a Tunisian Company

Due to the widespread reputation of their handmade calzone, they decided to buy a machine to meet the growing demand or the future…

Danish Pastry Industrial Production Line for an Indian Company

The client supplies Danish pastries, chapatis, Mille-feuilles and cinnamon rolls, and they wished to upgrade their production capacity in order to increase the revenue…

Semi-Automatic Blini Production Equipment Designed with Soft Pancake Stacker

Our agent gave a test run with ANKO's SRP for making blini, but failed to arrange them in a pile. Thus, ANKO's engineers developed…

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

The Noodle Extruder can be used to produce Spaghetti, Noodle and Noodles with Multi Structured, such as heart-shaped, fish-shaped, dumbbell-shaped, and…

Dumpling Machine Helps to Increase Capacity and Standardize Products

Consumers really liked the handmade dumplings, but "sold out" was the most important issue with which the company had to deal…

Shrimp Spring Roll Pastry Machinery Design for an American Company

As for spring roll pastry import, high cost and quality degradation caused by rising temperature during shipping prompted the client to purchase a machine…

Calzone Automatic Production Machinery Design for a Tunisian Company

Due to the widespread reputation of their handmade calzone, they decided to buy a machine to meet the growing demand or the future…

Danish Pastry Industrial Production Line for an Indian Company

The client supplies Danish pastries, chapatis, Mille-feuilles and cinnamon rolls, and they wished to upgrade their production capacity in order to increase the revenue…

Semi-Automatic Blini Production Equipment Designed with Soft Pancake Stacker

Our agent gave a test run with ANKO's SRP for making blini, but failed to arrange them in a pile. Thus, ANKO's engineers developed…

East African Chapati (Paratha) Customized Production Line Design for a Kenyan Company

The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO's products and services…

ANKO NDL-100 Noodle Extruder Launch for Noodle Manufacturers

The Noodle Extruder can be used to produce Spaghetti, Noodle and Noodles with Multi Structured, such as heart-shaped, fish-shaped, dumbbell-shaped, and…

Dumpling Machine Helps to Increase Capacity and Standardize Products

Consumers really liked the handmade dumplings, but "sold out" was the most important issue with which the company had to deal…

Shrimp Spring Roll Pastry Machinery Design for an American Company

As for spring roll pastry import, high cost and quality degradation caused by rising temperature during shipping prompted the client to purchase a machine…

The Best Selection - Get Started with Us to Discuss Your Needs

Automatic Layer & Stuffed Paratha Production Line

LP-3001 is fully automatic to produce similar products such as paratha, pie and the like. Placing well-mixed dough and margarine into hoppers is the only thing to do. Then the fully automatic production processes include dough pressing, margarine extruding, the first folding and sheeting, the second folding and sheeting, rolling, cutting into balls, and pressing to form tasty products. When the production line equips a filling machine, LP-3001 can form various tastes of stuffed pastries, such as curry pastries, barbecued pork pastries, bean paste pastries, etc. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More Info Compare searies machineCompare with Similar Models

Specifications

Capacity: 3,000 pcs/hr or 300 kg/hr

Features

- Voltage can be designated.

- The thickness of pizza base wrapper and the amount of filling can be adjusted by parameter setting.

- The shape of pizza base can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- DownloadsBest SellingRelated Food Solutions Type