Parotta

Indian Paratha Production Line and Food Manufacturing Solutions

Model no : SOL-PRT-0-1

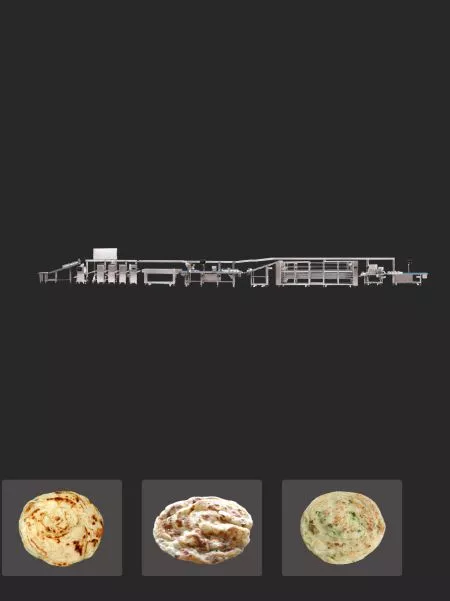

Looking for an automated solution for mass-producing parotta? ANKO’s Parotta Production Line creates ultra-thin 0.8mm translucent dough with a crispy, multi-layered texture. The line integrates rolling, oiling, resting, and shaping, requiring only three operators. Optional add-ons like freezing, X-ray inspection, and packaging ensure a complete production process. Flexible configuration options meet diverse market needs, delivering exceptional taste and efficient packaging. Fill out the inquiry form now to get your tailored production optimization plan!

Parotta Production Solutions Tailored to Meet Your Needs

Parotta, known for its crispy, multi-layered texture, has gained global popularity, from street vendors to chain restaurants. Its unique process involves folding, rolling, resting, and baking to achieve golden, flaky layers, perfect with curry or as a breakfast and snack option. This growing demand drives food manufacturers to explore scalable production.

ANKO’s machines replicate traditional handmade techniques, delivering authentic Indian flavors. Our food lab assists with recipe development and process optimization, while our expert team provides end-to-end support, including factory planning, staff training, and after-sales service. With modular equipment design, we tailor solutions for both chain restaurants and large-scale production, ensuring the perfect Parotta production system for your needs.

Food's Gallery

1

Rolls / Wraps

- Sheeting / Wrapping

Case Studies

Automatic Samosa Pastry Sheet Machinery Design for a Kuwait Company

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one…

Multipurpose Filling & Forming Machine - Machinery Design for a Tunisian Company

The client is an owner of a hotel chain in Tunisia. Speaking of cooking, their insistence on food has gained favor with visitors…

Rasgulla Automatic Production Line Design for an Indian Company

Rasgulla is a classic Indian sweet which can be produced by SD-97 series and RC-180 Rounding Conveyor. In order to increase production capacity and save labor costs…

Glutinous Rice Ball Machinery Designed to Solve Problem of Extruding Dry Filling

The client visited ANKO's booth at a Hong Kong exhibition for a solution to produce glutinous rice balls effectively…

A New Lachha Paratha Production Line Set-up for an Indian Company

In order to increase capacity and improve product quality, the idea of shifting manual to automatic production has been lingering in client's mind...

ANKO Lachha Paratha Production Line to Reduce Labor Cost and Increase Productivity

The client is a frozen food manufacturer, producing Indian food and selling to grocery stores and supermarkets...

Automatic Layered Paratha Production Line for a Bangladeshi Company

The client decided to run a paratha production line due to the popularity of paratha. He trusted ANKO with Turnkey Planning Consulting Services…

Automatic Samosa Pastry Sheet Machinery Design for a Kuwait Company

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one…

Multipurpose Filling & Forming Machine - Machinery Design for a Tunisian Company

The client is an owner of a hotel chain in Tunisia. Speaking of cooking, their insistence on food has gained favor with visitors…

Rasgulla Automatic Production Line Design for an Indian Company

Rasgulla is a classic Indian sweet which can be produced by SD-97 series and RC-180 Rounding Conveyor. In order to increase production capacity and save labor costs…

Glutinous Rice Ball Machinery Designed to Solve Problem of Extruding Dry Filling

The client visited ANKO's booth at a Hong Kong exhibition for a solution to produce glutinous rice balls effectively…

A New Lachha Paratha Production Line Set-up for an Indian Company

In order to increase capacity and improve product quality, the idea of shifting manual to automatic production has been lingering in client's mind...

ANKO Lachha Paratha Production Line to Reduce Labor Cost and Increase Productivity

The client is a frozen food manufacturer, producing Indian food and selling to grocery stores and supermarkets...

Automatic Layered Paratha Production Line for a Bangladeshi Company

The client decided to run a paratha production line due to the popularity of paratha. He trusted ANKO with Turnkey Planning Consulting Services…

Automatic Samosa Pastry Sheet Machinery Design for a Kuwait Company

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one…

The Best Selection - Get Started with Us to Discuss Your Needs

Lacha Paratha and Green Scallion Pie Production Line

The crispy layers of parathas or scallion pancakes are craved by people. ANKO's Lacha Paratha & Green Scallion Pie Production Line can produce parathas and scallion pancakes with extremely thin layers because it features a dough stretching device, which can stretch dough into a 0.8 mm thin sheet. By simply putting dough, scallions, and oil, the Lacha Paratha & Green Scallion Pie Production Line can mass-produce Chinese pancakes, scallion pancakes, and parathas automatically. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More Info Compare searies machineFrequently Operate with

Automatic Filming and Pressing Machine

The PP-2 Series is designed to press dough balls into a circle and cover them with plastic films and moreover, stack the final products in a pile. It can make scallion pancake, paratha, pizza base, and stuffed paratha. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More InfoCompare with Similar Models

Specifications

Capacity: 4,000 pcs/hr

Features

- Voltage can be designated.

- The thickness of parotta wrapper can be adjusted by parameter setting.

- The shape of parotta can be different by quickly exchanging the forming mold sets.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- DownloadsBest SellingRelated Food Solutions Type