Chinese Flaky Pastry

Automated Chinese Flaky Pastry Production Line

Model no : SOL-CFP-0-1

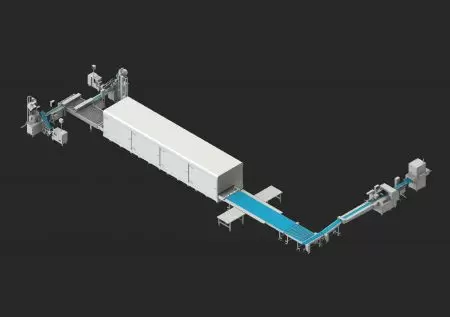

Looking for an automated solution for mass-producing Chinese Flaky Pastry? ANKO’s production line can produce up to 6,300 pieces per hour, creating crispy, multi-layered pastry with perfectly filled interiors in one go. Our complete turnkey solution covers preparation, molding, and packaging, with fully automated design that reduces labor costs by up to 70%, helping food manufacturers create competitive products. Want to boost your production efficiency? Request a professional solution today!

Professional Chinese Flaky Pastry Production Plant Planner

Chinese Flaky Pastry is known for its multi-layered, crispy texture, with flavors including sweet red bean, winter melon, savory meat fillings, and salted egg yolk. This traditional snack has become a global favorite, gaining popularity beyond Asia and becoming a key product for many food manufacturers. ANKO’s "LP-3001 Automatic Layer & Stuffed Paratha Production Line" offers precise layering and reliable performance, making it the perfect partner for scaling up production.

We offer comprehensive solutions, from small-scale facilities to large production lines, integrating preparation, molding, packaging, and freezing equipment to meet international hygiene standards. Our flexible equipment configurations cater to your production needs, backed by professional technical support to help you gain a competitive edge. Contact us today to explore your tailored production solution.

1

Rolls / Wraps

- Sheeting / Wrapping

The Best Selection - Get Started with Us to Discuss Your Needs

Automatic Layer & Stuffed Paratha Production Line

LP-3001 is fully automatic to produce similar products such as paratha, pie and the like. Placing well-mixed dough and margarine into hoppers is the only thing to do. Then the fully automatic production processes include dough pressing, margarine extruding, the first folding and sheeting, the second folding and sheeting, rolling, cutting into balls, and pressing to form tasty products. When the production line equips a filling machine, LP-3001 can form various tastes of stuffed pastries, such as curry pastries, barbecued pork pastries, bean paste pastries, etc. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More Info Compare searies machineCompare with Similar Models

| Model no | Automatic Layer & Stuffed Paratha Production Line LP-3001 | Automatic Filming and Pressing Machine PP-2 Series |

|---|---|---|

| Description | Special structure can make dough balls with up to 32 layers | The thickness and size of product can be adjusted as required |

| Capacity | 3,000 pcs/hr | 1,500 pcs/hr |

| Weight | 40 - 130 g/pc | - |

| More Info | More Info |

Specifications

Capacity: 6,300 pcs/hr

Features

- Voltage can be designated.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

Would you like to find machines or integrated production line?

- DownloadsBest SellingRelated Food Solutions Type