Tapioca Pearls

Your Tapioca Pearls Production Planning And Tapioca Pearls Recipe Consultant.

Model no : SOL-TPP-S-1

Bubble tea has become a hit in the world. To meet a surge in demand for tapioca pearls, ANKO offers you “one-stop” “tapioca pearls production solution”. We not only provide machines, including sieving machine, mixing machine, cutting & rounding machine, packaging machine, and so on, for automatic production of tapioca pearls products, but also help you plan a comprehensive production line and deploy human resources. ANKO’s experienced executives will be here to give you the most professional advice on making tapioca pearls. In the solution below, the machines can be adjusted in model and quantity according to real production needs. Want to get a quick quote and consultant? Please click the button below and fill out the form.

About Tapioca Pearls Production Solution

With the "Automatic Cutting and Rounding Machine", the production of tapioca pearls that used to be complicated is now faster and easier. Simply by putting starch dough into the hopper, the machine can automatically make tapioca pearls by pressing, cutting, and rounding. Both small pearls and boba pearls can be made by the machine. Dough texture remains intact after forming, which makes the final products as delicate and delicious as handmade ones. Moreover, the machine is easy to use with no experience needed and equipped with a unique dusting device to prevent tapioca pearls from sticking.

Food's Gallery

Turnkey and Production Planning

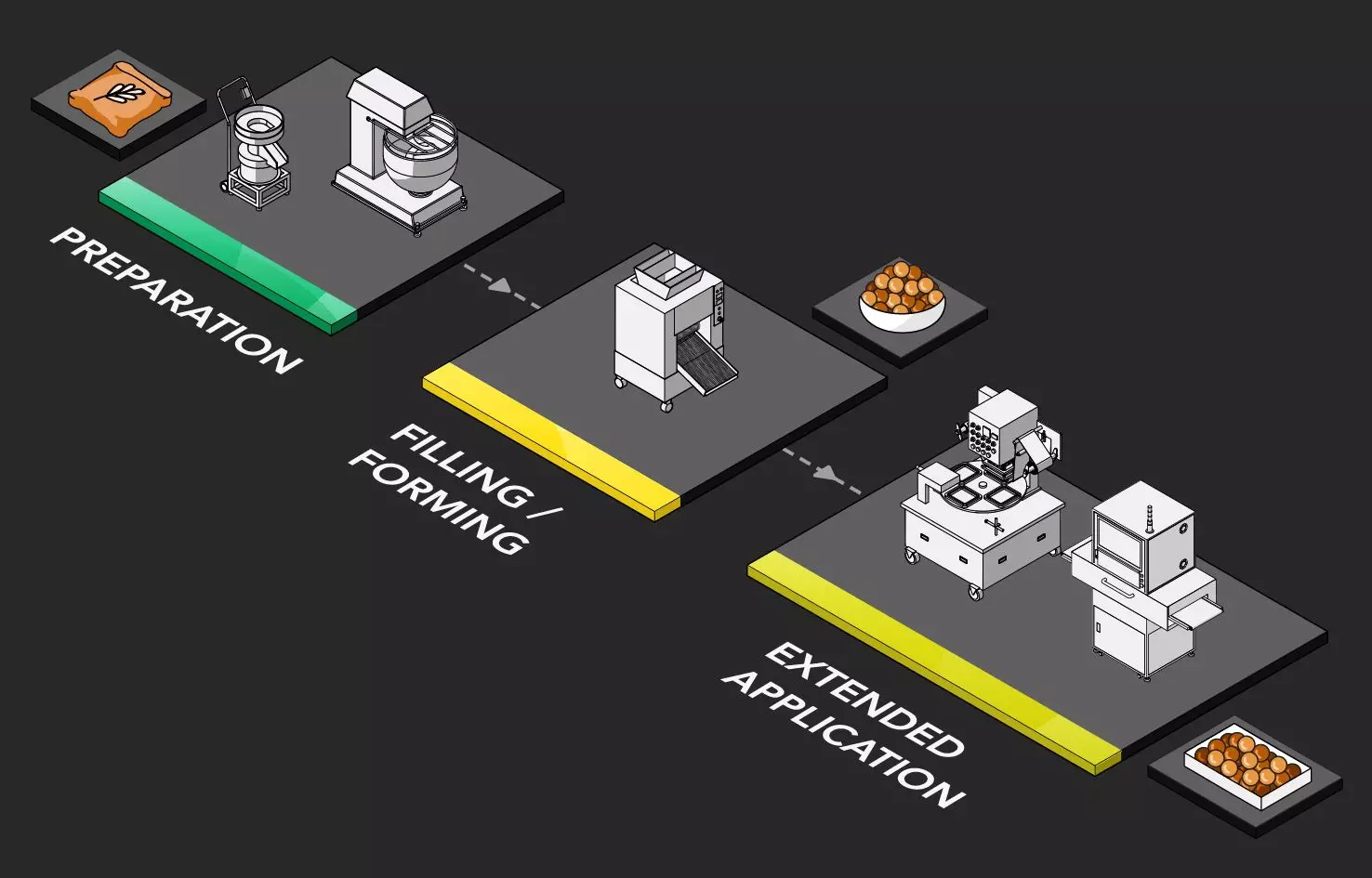

1

Preparation

- Sieving Mixing

2

Filling / Forming

- Rounding

3

Extended Application

- Sealing Quality Control

Case Studies

Pineapple Cake Automatic Production Line Set up for New Product Launch

The client found that Taiwanese pineapple cake is very popular and delicious, so he decided to produce pineapple cakes and sell…

Glutinous Rice Ball Machinery Designed to Solve Problem of Extruding Dry Filling

The client visited ANKO's booth at a Hong Kong exhibition for a solution to produce glutinous rice balls effectively…

Table Type Automatic Encrusting And Filling Machine-Machinery Design for UK Company

In order to reduce labor cost, the client went to a machinery show and was impressed with ANKO's food machine…

Ready-to-eat Tapioca Pearl Recipe Development for a Taiwanese Company

This Taiwanese client had no experience in tapioca pearl production and was referred by the OEM company to consult with ANKO…

Sweet Potato Ball Production Equipment Designed to Produce Small Sweet Potato Balls

The client owned a machinery which was not able to produce small sweet potato balls. They found that ANKO has…

Automatic Encrusting and Forming Machine - Machinery Design for Hong Kong Company

With current frozen equipment and packaging machinery, they would like to increase efficiency and develop other…

Pineapple Cake Automatic Production Line Set up for New Product Launch

The client found that Taiwanese pineapple cake is very popular and delicious, so he decided to produce pineapple cakes and sell…

Glutinous Rice Ball Machinery Designed to Solve Problem of Extruding Dry Filling

The client visited ANKO's booth at a Hong Kong exhibition for a solution to produce glutinous rice balls effectively…

Table Type Automatic Encrusting And Filling Machine-Machinery Design for UK Company

In order to reduce labor cost, the client went to a machinery show and was impressed with ANKO's food machine…

Ready-to-eat Tapioca Pearl Recipe Development for a Taiwanese Company

This Taiwanese client had no experience in tapioca pearl production and was referred by the OEM company to consult with ANKO…

Sweet Potato Ball Production Equipment Designed to Produce Small Sweet Potato Balls

The client owned a machinery which was not able to produce small sweet potato balls. They found that ANKO has…

Automatic Encrusting and Forming Machine - Machinery Design for Hong Kong Company

With current frozen equipment and packaging machinery, they would like to increase efficiency and develop other…

The Best Selection - Get Started with Us to Discuss Your Needs

Automatic Cutting and Rounding Machine

The GD-18B Automatic Cutting and Rounding Machine is one of ANKO's best-selling machines. It can make various products with great taste and texture, such as tang yuan, taro ball, sweet potato ball, tapioca pearl, etc. The compact design of the machine allows it to be installed in little dessert or beverage shops. Want to get a quick quote and consultant? Please click the button below and fill out the form.

More InfoSpecifications

Capacity:30 kg/hr or 33,000 pc/hr

*Based on 0.9-gram tapioca pearls

Features

- Voltage can be designated.

- All machines meet food hygiene regulations.

- Can change, remove, add machines according to the real needs.

- Can give suggestions on space requirement, layout design, and manpower planning.

- Production output may vary based on customer recipes, sizes, and shapes. This specification is for reference only. Any adjustments will be made without further notice.

Suitable for

-

Supply Chain BusinessesCentral kitchen, Food factory, Kitchen & Equipment Supplier

-

Equipment & InvestmentMachine distributor, Food Industry Investor

-

Food ServiceCloud kitchen, Chain Restaurant, Cafeteria, Hotel, School

What services and benefits are covered in the solution?

One-stop tapioca pearls production solution allowing you to get all services from purchase to installation from one single place

In order to automatically make tapioca pearls, you have to buy a series of machines for mixing, forming, and packing. Do you feel that you spend a lot of time and effort contacting different suppliers? ANKO provides tapioca pearls production solution to meet all your needs. Not only equipment, but also a professional food lab is available to help you ensure the machine and machine-made food satisfy your needs. Moreover, when your machine arrived, our installation and training services can help you save time and effort. All you need will be completed in one procurement.

Tapioca pearls equipment integration and effectiveness assessment are conducted by our professionals

With 45 years' experience in providing services for numerous food factories and central kitchens, ANKO is your professional turnkey project consultant in tapioca pearls production. Based on your factory size and manpower, we can provide custom-made suggestions of tapioca pearls equipment configuration and integration, wiring, production plan, and other details. In addition, ANKO assists you in thoroughly assessing the effectiveness of a solution and estimating manpower and time that could be reduced, which allows you to focus on operation and market development.

Maintain tapioca pearls production efficiency, save time on primary decision

Many owners might have unpleasant experience of contacting customer service for tapioca pearls machine repair, especially when a problem is handled by different customer service specialists. The long process might affect tapioca pearls production capacity and lead to unexpected losses caused by shutdown and delivery delays. Hand over your concerns to ANKO! We provide a custom-made one-stop solution for you and assign a specific person to help all things from purchase to repair. Moreover, our comprehensive database records all your machine details to reduce the risks of loss someday.

Food consultants with 45 years of experience help you with your tapioca pearls recipe

With 45 years of experience in the food machine industry, a wealth of market information, and detailed observation of the industry, ANKO can provide suggestions for equipment upgrades. Through direct interaction with our customers from 113 countries, we are well acquainted with the world's tapioca pearls and other related foods as well as consumer preferences. Whether it is about texture or taste, ANKO can offer advices on your recipes, even production and strategy in your target market with our general knowledge.

How to get a solution proposal?

Let us know your needs via "ADD TO INQUIRY LIST" above or phone. ANKO's professional consultants will assess your product and current plan, and then have a further discussion with you. According to your situation, we will recommend a solution that is suitable for you. If you have any questions about machines and production, please feel free to contact us for further discussion.

- Best SellingRelated Food Solutions Type