-

English

- 中文 (繁體)

- 中文 (简体)

- English

- Русский

- العربية

- Azərbaycan

- Беларуская

- Български

- বাঙ্গালী

- česky

- Dansk

- Deutsch

- Ελληνικά

- Español

- Eesti

- فارسی

- Suomen

- Français

- Gaeilge

- हिन्दी

- Hrvatska

- Magyar

- Indonesia

- Italiano

- 日本語

- 한국어

- Lietuviškai

- Latviešu

- Bahasa Melayu

- Nederlands

- Polska

- Português

- Română

- slovenčina

- Svenska

- ไทย

- Filipino

- Türkçe

- українська

- Việt

- Support

Expert of Food Machine and Production Line Solutions | ANKO FOOD MACHINE CO., LTD.

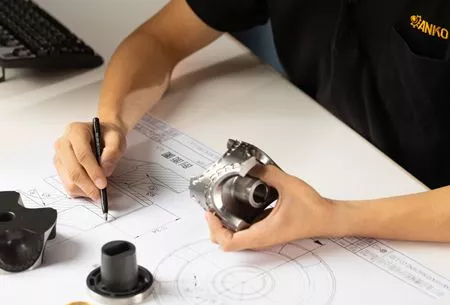

ANKO Food Machine Company is the expert in siomai, wonton, baozi, tapioca pearls, dumpling, spring roll machine and provides consulting services. ANKO began by selling frozen food processing equipment . We own 70% of the frozen food processing equipment market in Taiwan and have also sold them to more than 114 countries.

ANKO

Taste Of Tradition, Pioneer In Production

47

Years excellent experience

114

Customers across countries

700

Collected recipes

Food Solutions We Offer

According to your required production capacity, our consulting team is able to provide comprehensive food production planning.

Latest News

Recap: In-Depth Analysis of the Empanada Production Line

Missed the online demonstration of our empanada production line? No worries! Fill out the form now to access the full replay and gain valuable insights into automated high-volume production solutions.

Dumplings – A Humble Staple Food becoming a Global Phenomenon

Dumplings reflect the food traditions of their country of origin, such as Chinese Jiaozi, Japanese crispy Gyoza, Tibetan Momo, Tortellini from Italy, and the sweet or savory Polish Pierogi.

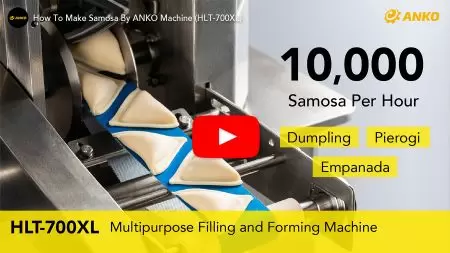

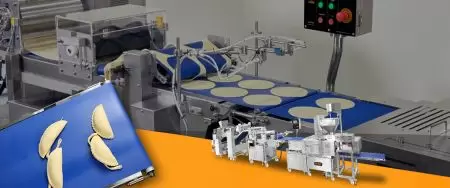

High-Capacity Empanada Machines for Wholesale Success

ANKO, a leading manufacturer of food machines and solutions provider, has announced the launch of a new Empanada-making machine featuring an innovative modular design. The EMP-3000 Empanada Making Machine is designed to deliver exceptional efficiency, productivity, and customization options for food...

Gen Z’s Value of Novelty Dining Experiences – A Key to Your Success

Gen Z consumers crave food with bold and spicy flavors; they also prioritize health and sustainability. Therefore, minimally processed and eco-friendly products are popular among this young generation.

2025 iba

ANKO will showcase our best-selling food machines at the iba trade fair in Germany, May 18-22, 2025, Hall 12, Booth A25. Our team will present fully automated food production solutions to the European market.

2025 Event List

In 2025, ANKO is set to make a significant global presence by participating in exhibitions across five continents. Our machines are designed to produce authentic ethnic foods from diverse cultures, including dumplings, spring rolls, soup dumplings, shumai, empanadas, samosa, Mexican burritos, kibble,...

Recap: In-Depth Analysis of the Empanada Production Line

Missed the online demonstration of our empanada production line? No worries! Fill out the form now to access the full replay and gain valuable insights into automated high-volume production solutions.

Dumplings – A Humble Staple Food becoming a Global Phenomenon

Dumplings reflect the food traditions of their country of origin, such as Chinese Jiaozi, Japanese crispy Gyoza, Tibetan Momo, Tortellini from Italy, and the sweet or savory Polish Pierogi.

High-Capacity Empanada Machines for Wholesale Success

ANKO, a leading manufacturer of food machines and solutions provider, has announced the launch of a new Empanada-making machine featuring an innovative modular design. The EMP-3000 Empanada Making Machine is designed to deliver exceptional efficiency, productivity, and customization options for food...

Gen Z’s Value of Novelty Dining Experiences – A Key to Your Success

Gen Z consumers crave food with bold and spicy flavors; they also prioritize health and sustainability. Therefore, minimally processed and eco-friendly products are popular among this young generation.

2025 iba

ANKO will showcase our best-selling food machines at the iba trade fair in Germany, May 18-22, 2025, Hall 12, Booth A25. Our team will present fully automated food production solutions to the European market.

2025 Event List

In 2025, ANKO is set to make a significant global presence by participating in exhibitions across five continents. Our machines are designed to produce authentic ethnic foods from diverse cultures, including dumplings, spring rolls, soup dumplings, shumai, empanadas, samosa, Mexican burritos, kibble,...

Case Study

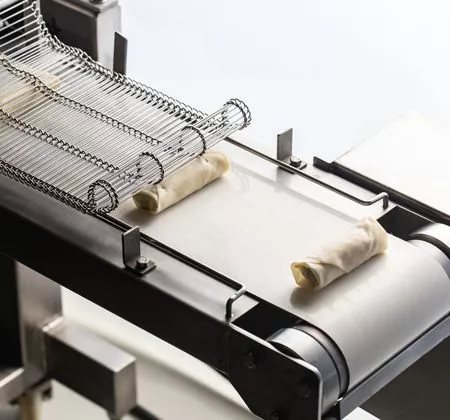

Machinery Design for a Jordanian Company

ANKO Spring Roll Production Line. The client's products are Halal food, including spring roll with vegetable stuffing, chicken and onion stuffing, cheese stuffing as well as beef stuffing, permissible...

Food Factory / Food Processing Equipment Solutions

To increase food production capacity and expand food product line are the main reasons that food factory owners contact ANKO.

Machinery Design for an Indian Company

ANKO Automatic Layer Paratha Production Line. The quality, weight, and size of the handmade paratha aren't consistent and the production capacity is low.

Automatic Dumpling Production Equipment Designed to Enhance a Food's Handmade Look

Customers want to increase production capacity by moving from manual to automatic production. However, sometimes machine-made dumplings cannot meet their required shape.

Frozen Food / Food Processing Equipment Solutions

Due to longer shelf-life and convenience, the demand for frozen food is soaring. To make frozen food, in addition to food forming machines, you may need a specialist freezer, minor adjustments to your...

Automatic shumai machine designed to solve supply shortages of shumai

Recently, due to the COVID-19 lockdown, the demand for frozen food and ready-to-eat food is growing while people are unable or less willing to eat in restaurants.

Machinery Design for a Jordanian Company

ANKO Spring Roll Production Line. The client's products are Halal food, including spring roll with vegetable stuffing, chicken and onion stuffing, cheese stuffing as well as beef stuffing, permissible...

Food Factory / Food Processing Equipment Solutions

To increase food production capacity and expand food product line are the main reasons that food factory owners contact ANKO.

Machinery Design for an Indian Company

ANKO Automatic Layer Paratha Production Line. The quality, weight, and size of the handmade paratha aren't consistent and the production capacity is low.

Automatic Dumpling Production Equipment Designed to Enhance a Food's Handmade Look

Customers want to increase production capacity by moving from manual to automatic production. However, sometimes machine-made dumplings cannot meet their required shape.

Frozen Food / Food Processing Equipment Solutions

Due to longer shelf-life and convenience, the demand for frozen food is soaring. To make frozen food, in addition to food forming machines, you may need a specialist freezer, minor adjustments to your...

Automatic shumai machine designed to solve supply shortages of shumai

Recently, due to the COVID-19 lockdown, the demand for frozen food and ready-to-eat food is growing while people are unable or less willing to eat in restaurants.