Expert of Food Machine and Production Line Solutions | ANKO FOOD MACHINE CO., LTD.

ANKO Food Machine Company is the expert in siomai, wonton, baozi, tapioca pearls, dumpling, spring roll machine and provides consulting services. ANKO began by selling frozen food processing equipment . We own 70% of the frozen food processing equipment market in Taiwan and have also sold them to more than 114 countries.

ANKO

Taste Of Tradition, Pioneer In Production

48

Years excellent experience

114

Customers across countries

700

Collected recipes

Food Solutions We Offer

According to your required production capacity, our consulting team is able to provide comprehensive food production planning.

Latest News

In-Depth Analysis: Food Manufacturers Facing Labor Shortages Practical Automation Strategies|ProductionGuide

Labor Shortages Are Structural, Not Temporary. Between 2024 and 2025, the ANKO team has seen a sharp increase in inquiries related to labor management challenges. This is no longer a regional issue—it is a global structural problem affecting food factories and chain foodservice operators alike. According...

2026 Event List

In 2026, ANKO is set to make a significant global presence by participating in exhibitions across five continents. Our machines are designed to produce authentic ethnic foods from diverse cultures, including dumplings, spring rolls, soup dumplings, shumai, empanadas, samosa, Mexican burritos, kibble,...

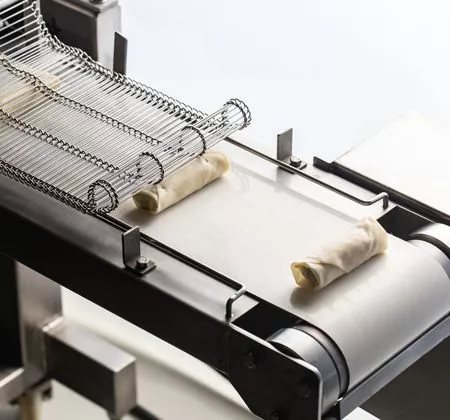

Online Overview of Automated Food Production Lines

Watch ANKO’s food machine in live operation and see the complete automated process from forming to mass production. Gain clear insight into high-capacity, low-labor configurations, ideal for food factories evaluating production line upgrades and capacity expansion.

Boost Production & Save on Taxes with Section 179

Starting in 2025, the Section 179 small business expensing cap has doubled from $1.25 million to $2.5 million, giving food manufacturers an exceptional opportunity to upgrade production while saving on taxes. Under Section 179 of the U.S. Internal Revenue Code, businesses may deduct the full cost of qualifying...

Flatbread Automation: 40,000 Daily Output with 70% Less Labor

As of 2024, the U.S. food and beverage manufacturing sector employed only 1.747 million people, despite the food manufacturing industry being highly labor-dependent. More than a third of companies report that labor shortages lead to difficulties in maintaining consistent product quality and hygiene standards,...

From Taiwan to Europe: ANKO Experience Center Opens in the Netherlands

Starting in Asia, expanding through the Americas, and now reaching Europe—ANKO Food Machine continues to realize its vision: "To provide trustworthy and delicious food production solutions and become the best partner for customers on their growth journey." Following the establishment of its first overseas...

Case Study

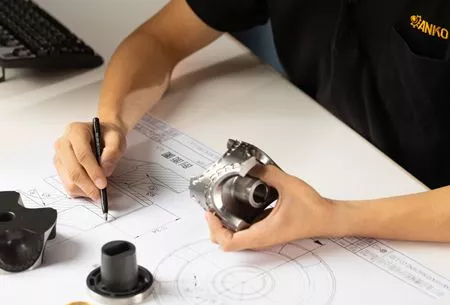

Automatic Dumpling Production Equipment Designed to Enhance a Food's Handmade Look

Customers want to increase production capacity by moving from manual to automatic production. However, sometimes machine-made dumplings cannot meet their required shape.

Frozen Food / Food Processing Equipment Solutions

Due to longer shelf-life and convenience, the demand for frozen food is soaring. To make frozen food, in addition to food forming machines, you may need a specialist freezer, minor adjustments to your...

Automatic shumai machine designed to solve supply shortages of shumai

Recently, due to the COVID-19 lockdown, the demand for frozen food and ready-to-eat food is growing while people are unable or less willing to eat in restaurants.

Machinery Design for a Jordanian Company

ANKO Spring Roll Production Line. The client's products are Halal food, including spring roll with vegetable stuffing, chicken and onion stuffing, cheese stuffing as well as beef stuffing, permissible...

Food Factory / Food Processing Equipment Solutions

To increase food production capacity and expand food product line are the main reasons that food factory owners contact ANKO.

Machinery Design for an Indian Company

ANKO Automatic Layer Paratha Production Line. The quality, weight, and size of the handmade paratha aren't consistent and the production capacity is low.