Integrated Burrito Production Line

Model no : SOL-BRT-T-1

ANKO’s integrated burrito production line includes ten stations—from dough preparation, filling, rolling, cooling, freezing, weighing, X-ray inspection, to packaging and case sealing—each equipped with dedicated machines. With just 4–5 operators, it ensures stable, high-capacity burrito production. Designed for high capacity with minimum manpower, it's the ideal solution for the burrito market in Europe and the Americas. Click the button below to complete the form to receive more information.

1

front-end

- ①Dough Softening and Transfer

- ②Dough Feeding System

2

mid-section

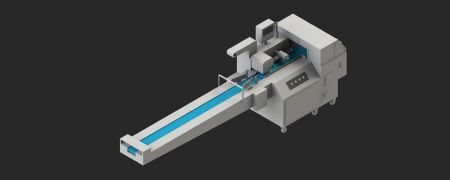

- ③Burrito Forming Machine

3

back-end

- ⑤IQF / Freezer

- ⑥Packaging Device

- ⑧Delta Robot

- ⑨Carton Sealer

4

quality control

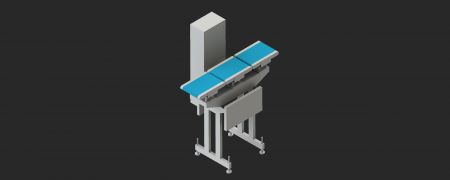

- ④Weight Inspection

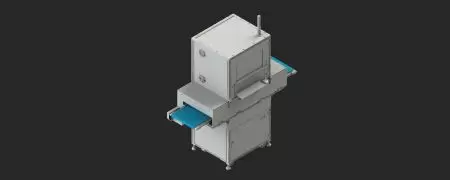

- ⑦X-Ray Inspection

- ➉Environmental Monitoring

➉Environmental Monitoring

Combining temperature and humidity monitoring with smart management, users can customize alert thresholds. When data exceeds the set range, instant mobile notifications are sent to reduce losses and enhance management efficiency. It also provides environmental data analysis and historical reporting features, enabling a high level of facility condition monitoring. ※Limited to regional sales

Features

-

Ultra-high production capacity configurationANKO customizes the integrated Burrito production line to meet your specific production capacity and product requirements.

-

Modularized Production ComponentsThe integrated Burrito production line consists of various components. ANKO can integrate various options for feeding equipment, forming machines, automatic aligning devices, quality inspection machines, and cooking equipment into an existing production line configuration.

-

Construction of highly automated factoriesThe integrated Burrito production line improves overall production efficiency, and significantly reduces labor requirements and cost. Giving you competitive advantages.

-

Ensure quality, health, and food safetyA fully automated production line with feeding equipment, conveyor belts, automatic aligning and rack loading machines, plays a crucial role in reducing human error. This, in turn, significantly reduces hazards caused by artificial contaminants ensuring high quality Burrito production, and greater overall food safety.

-

Gain Complete Control Over Environmental ChangesCombining intelligent temperature and humidity monitoring with efficient management, the professional team at Fox-Tech offers comprehensive solutions. For assistance, please contact: service@fox-tech.co or visit the Fox-Tech website.

- Best Selling